В современной промышленности надежность и эффективность являются критически важными факторами для успеха любого предприятия. Одним из ключевых элементов, обеспечивающих эти качества, являются алюминиевые детали, произведенные методом литья под давлением. Этот процесс позволяет создавать компоненты с высокой точностью, прочностью и долговечностью, что делает их незаменимыми в различных отраслях, от автомобилестроения до аэрокосмической индустрии. В этой статье мы подробно рассмотрим, почему высококачественные алюминиевые детали, отлитые под давлением, являются оптимальным выбором для ваших промышленных нужд, и как они способствуют повышению надежности и производительности.

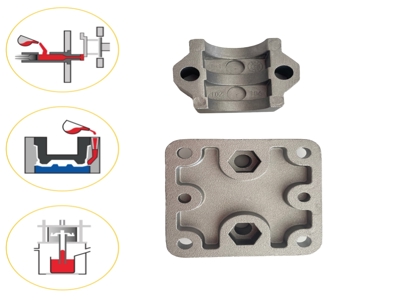

Литье под давлением — это высокотехнологичный процесс, при котором расплавленный алюминий впрыскивается под высоким давлением в пресс-форму, где он охлаждается и затвердевает, образуя готовую деталь. Этот метод известен своей способностью производить сложные геометрические формы с минимальными допусками, что идеально подходит для массового производства. Алюминий, как материал, обладает уникальными свойствами: он легкий, коррозионно-стойкий, обладает высокой теплопроводностью и легко поддается обработке. Сочетание этих характеристик с технологией литья под давлением делает алюминиевые детали исключительно востребованными в промышленности.

История литья под давлением насчитывает более века, начиная с первых экспериментов в конце XIX века. Сегодня, благодаря advancements в материалах и оборудовании, этот процесс достиг невероятного уровня точности и эффективности. Например, современные машины для литья под давлением могут работать с давлениями до нескольких тысяч бар, обеспечивая равномерное заполнение формы и минимизируя дефекты. Это позволяет производить детали, которые не только соответствуют строгим промышленным стандартам, но и превосходят их по качеству.

В контексте промышленной надежности, алюминиевые детали, отлитые под давлением, предлагают множество преимуществ. Они снижают вес конечных продуктов, что особенно важно в отраслях, где каждый грамм имеет значение, таких как авиация или автомобилестроение. Кроме того, их коррозионная стойкость延长 срок службы оборудования, уменьшая затраты на обслуживание и замену. В следующих разделах мы углубимся в детали этого процесса, его преимущества и практические применения.

Одним из главных преимуществ алюминиевых деталей, произведенных методом литья под давлением, является их высокая прочность при малом весе. Алюминиевые сплавы, такие как A380 или A356, обладают excellent mechanical properties, включая tensile strength и ударную вязкость, что делает их suitable для нагрузочных applications. Это особенно ценно в automotive industry, где reduction in vehicle weight leads to improved fuel efficiency and lower emissions. For instance, a study by the International Aluminum Institute showed that using aluminum components can reduce a car's weight by up to 40%, resulting in significant environmental benefits.

Another key advantage is the precision and consistency achieved through pressure die casting. The process allows for tight tolerances, often within ±0.1 mm, which is crucial for components that must fit perfectly in assemblies. This reduces the need for secondary machining, saving time and costs. Moreover, the surface finish of die-cast aluminum parts is typically smooth and requires minimal post-processing, enhancing their aesthetic appeal and functional performance. In industries like electronics, where components must be both durable and visually appealing, this is a major plus.

Cost-effectiveness is another significant benefit. While the initial tooling costs for die casting can be high, the per-unit cost decreases with volume production due to high efficiency and automation. This makes it ideal for large-scale manufacturing runs. Additionally, aluminum is recyclable, and die-casting scrap can be reused, reducing waste and supporting sustainability goals. According to industry reports, recycling aluminum saves up to 95% of the energy required to produce new metal, making it an environmentally friendly choice.

Durability and corrosion resistance are also standout features. Aluminum naturally forms a protective oxide layer that prevents rust, making these parts suitable for harsh environments, such as marine or outdoor applications. Combined with the ability to add protective coatings or anodizing, die-cast aluminum components can last for decades without degradation. This reliability translates to lower maintenance costs and increased uptime for industrial equipment, ultimately boosting productivity and profitability.

Процесс литья под давлением начинается с проектирования пресс-формы, которая определяет форму и размеры конечной детали. Это критический этап, требующий точных расчетов и использования CAD software для обеспечения оптимального flow of molten metal and minimal shrinkage. Современные технологии, такие как simulation software, allow engineers to predict and mitigate potential issues like porosity or warping before production begins. This upfront investment in design pays off in higher quality and fewer defects down the line.

Once the mold is ready, the actual casting process involves melting aluminum ingots in a furnace at temperatures around 600-700°C. The molten metal is then injected into the mold cavity under high pressure, typically ranging from 100 to 1000 bar, depending on the part complexity. The pressure ensures that the metal fills every intricate detail of the mold, resulting in precise and uniform parts. After injection, the metal cools and solidifies quickly, and the mold is opened to eject the finished part. Cycle times can be as short as a few seconds for small components, enabling high-volume production.

Post-casting processes may include trimming excess material, deburring, and surface treatments like painting or plating to enhance appearance and performance. Quality control is integral throughout, with inspections using techniques like X-ray or ultrasonic testing to detect internal defects. This rigorous approach ensures that every part meets specified standards, providing reliability that industries depend on. For example, in the aerospace sector, where safety is paramount, die-cast components undergo extensive testing to certify their integrity.

Advancements in technology continue to improve the die-casting process. Automation and robotics are increasingly used to handle molds and parts, reducing human error and increasing efficiency. Additionally, developments in alloy compositions and heat treatment processes allow for tailored properties, such as increased hardness or thermal resistance, expanding the applications of die-cast aluminum parts. These innovations make the process more adaptable and cost-effective for diverse industrial needs.

Алюминиевые детали, отлитые под давлением, находят широкое применение across multiple industries due to their versatility and performance. In the automotive industry, they are used for engine blocks, transmission cases, and structural components, where their light weight contributes to fuel efficiency and reduced emissions. Major manufacturers like Tesla and Toyota incorporate die-cast aluminum parts to achieve lighter, more efficient vehicles. For instance, the use of aluminum die-castings in electric vehicles helps offset the weight of batteries, improving range and performance.

In aerospace, these components are critical for airframes, landing gear, and engine parts, where strength-to-weight ratio is essential. The ability to produce complex shapes with high precision allows for optimized aerodynamics and reduced assembly times. Companies like Boeing and Airbus rely on die-cast aluminum for parts that must withstand extreme conditions while minimizing weight. This not only enhances safety but also reduces operational costs over the lifespan of the aircraft.

The electronics industry benefits from the thermal conductivity and electromagnetic shielding properties of aluminum. Die-cast parts are used in heat sinks, enclosures, and connectors for devices like smartphones, computers, and servers. Their ability to dissipate heat efficiently prevents overheating and ensures reliable operation. For example, Apple uses die-cast aluminum in MacBook casings, combining durability with a sleek design that appeals to consumers.

Other sectors, such as construction, medical devices, and consumer goods, also leverage die-cast aluminum components. In construction, they are used for window frames, door handles, and structural supports, offering durability and corrosion resistance. In medical devices, precision-made parts ensure hygiene and reliability in equipment like surgical instruments or imaging machines. The adaptability of die-casting allows for customization to meet specific industry requirements, making it a go-to solution for innovative applications.

To ensure high quality, die-cast aluminum parts must meet specific characteristics and standards. Mechanical properties, such as tensile strength, hardness, and elongation, are critical and are often specified by standards like ASTM or ISO. For instance, ASTM B85 outlines requirements for aluminum alloy die castings, ensuring consistency and performance. These standards help manufacturers and customers verify that parts will perform as expected under operational stresses.

Surface quality is another important aspect, with smooth finishes free from defects like pores or cracks being essential for both functional and aesthetic reasons. Dimensional accuracy is verified through coordinate measuring machines (CMM) or optical scanners to confirm that tolerances are within acceptable limits. In industries like automotive or aerospace, where parts must integrate seamlessly with other components, even minor deviations can lead to failures, so rigorous quality control is non-negotiable.

Material composition plays a key role in determining properties. Common aluminum alloys for die casting include A380, which offers good fluidity and strength, and A356, known for its excellent ductility and corrosion resistance. The choice of alloy depends on the application; for example, A380 is often used for high-volume production due to its castability, while A356 is preferred for parts requiring better mechanical properties. Heat treatment processes, such as solution treatment and aging, can further enhance these properties, tailoring the parts to specific needs.

Environmental and sustainability standards are increasingly important. Certifications like ISO 14001 for environmental management ensure that manufacturing processes minimize impact, such as reducing energy consumption and waste. Recycling practices are integral, with many die-casting facilities implementing closed-loop systems to reuse scrap metal. This not only supports corporate sustainability goals but also appeals to eco-conscious consumers and regulators, adding value beyond mere performance.

The future of die-cast aluminum parts is shaped by ongoing innovations aimed at enhancing efficiency, sustainability, and functionality. One emerging trend is the integration of additive manufacturing, or 3D printing, with traditional die casting. For example, 3D-printed molds can be produced faster and with more complex geometries, reducing lead times and costs for prototyping and small batches. This hybrid approach allows for greater flexibility in design and production.

Advancements in alloy development are also on the horizon. Researchers are working on new aluminum alloys with improved properties, such as higher strength at elevated temperatures or better wear resistance. These innovations could expand applications into more demanding environments, like high-performance motorsports or renewable energy systems, where components must endure extreme conditions without failure.

Automation and Industry 4.0 technologies are transforming die-casting facilities into smart factories. IoT sensors and data analytics enable real-time monitoring of the casting process, predicting maintenance needs and optimizing parameters for better quality. This leads to higher productivity and reduced downtime, making die casting more competitive. For instance, predictive analytics can alert operators to potential defects before they occur, ensuring consistent output.

Sustainability will continue to be a driving force, with increased focus on circular economy principles. Efforts to reduce carbon footprint through energy-efficient furnaces and renewable energy sources are gaining traction. Additionally, bio-based or recycled aluminum sources are being explored to further minimize environmental impact. As industries worldwide prioritize green initiatives, die-cast aluminum parts are poised to play a key role in sustainable manufacturing.

В заключение, высококачественные алюминиевые детали, отлитые под давлением, предлагают unparalleled benefits for industrial reliability. Their combination of light weight, strength, precision, and cost-effectiveness makes them ideal for a wide range of applications. By choosing these components, businesses can enhance product performance, reduce operational costs, and contribute to sustainability goals. Whether in automotive, aerospace, electronics, or other sectors, die-cast aluminum parts provide the durability and efficiency needed to thrive in today's competitive market.

Investing in quality die casting is not just about the immediate product; it's about building a foundation for long-term success. With advancements in technology and a growing emphasis on environmental responsibility, the future looks bright for this manufacturing method. We encourage you to explore how high-quality die-cast aluminum parts can transform your industrial projects and drive innovation forward.

For more information or to discuss your specific needs, contact our experts today. Together, we can create solutions that elevate your industry to new heights of reliability and excellence.