В современном быстро меняющемся промышленном ландшафте эффективность производства является ключевым фактором успеха для любого предприятия. Конкуренция на глобальном рынке требует от компаний не только снижения затрат, но и повышения качества продукции, ускорения сроков выпуска и адаптации к индивидуальным потребностям клиентов. Одним из мощных инструментов для достижения этих целей является использование заказных инженерных деталей. В этой статье мы подробно рассмотрим, почему кастомные компоненты могут кардинально улучшить ваше производство, и как их внедрение способствует оптимизации процессов, снижению издержек и увеличению общей продуктивности.

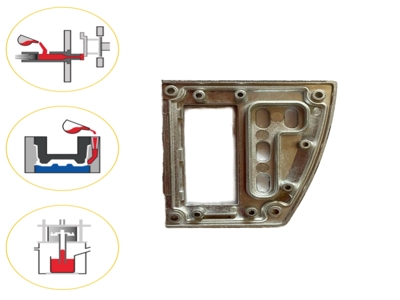

Заказные инженерные детали — это компоненты, спроектированные и изготовленные специально для конкретных применений, в отличие от стандартных или серийных деталей, которые производятся массово и могут не полностью соответствовать уникальным требованиям оборудования или процессов. Эти детали создаются с учетом точных спецификаций, таких как размеры, материалы, tolerances, и функциональные характеристики, что позволяет им идеально интегрироваться в существующие системы. Исторически, промышленность relied на стандартизированные детали для упрощения производства и снижения costs, но с развитием технологий, таких как CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), и additive manufacturing (3D-печать), создание custom деталей стало более доступным и экономически эффективным.

Использование заказных деталей не является новой концепцией; оно уходит корнями в early days машиностроения, когда инженеры проектировали components tailored для specific машин. Однако, в последние десятилетия, с ростом автоматизации и цифровизации, возможности для кастомизации expanded exponentially. Сегодня, предприятия across various отраслей, от automotive и aerospace до medical devices и consumer electronics, increasingly turn to custom engineering parts to gain competitive edge. This shift is driven by the need for higher precision, better performance, and greater flexibility in production lines.

В контексте повышения эффективности производства, заказные детали offer numerous advantages. Они позволяют optimize workflows, reduce waste, enhance product quality, and accelerate innovation. By focusing on the specific needs of a production process, companies can avoid compromises associated with off-the-shelf parts, which often lead to inefficiencies, downtime, and increased maintenance costs. Moreover, custom parts can be designed to improve ergonomics, safety, and sustainability, contributing to a more holistic approach to manufacturing excellence.

In this article, we will delve into the multifaceted benefits of custom engineering parts, supported by real-world examples, statistical data, and expert insights. We will explore how they contribute to cost reduction, quality improvement, production flexibility, and overall operational efficiency. Additionally, we will address common misconceptions and challenges associated with their adoption, providing practical advice for businesses looking to integrate custom parts into their operations. By the end, you will have a comprehensive understanding of why investing in custom engineering parts is a strategic move for any production-oriented organization.

Одним из наиболее значительных преимуществ заказных инженерных деталей является их potential для снижения общих затрат производства. На первый взгляд, custom детали may seem more expensive due to higher initial design and tooling costs compared to mass-produced standard parts. Однако, при правильном подходе, они can lead to substantial long-term savings. This is primarily achieved through optimization of design, which minimizes material waste, reduces energy consumption, and decreases the need for frequent replacements or repairs.

For instance, consider a manufacturing line that uses standard conveyor belts. These belts might not perfectly fit the specific layout or load requirements, leading to inefficiencies such as slippage, excessive wear, or even breakdowns. By designing a custom conveyor belt tailored to the exact dimensions and operational conditions, a company can reduce energy usage by up to 15-20%, as reported in studies by industry experts. Additionally, optimized design can extend the lifespan of the part, meaning fewer purchases over time and lower inventory costs.

Another aspect is the reduction in scrap and rework. Standard parts often require modifications or adaptations on-site, which can generate waste and increase labor costs. Custom parts, being designed to fit perfectly from the start, eliminate the need for such adjustments. According to data from the National Institute of Standards and Technology (NIST), businesses that switch to custom components report a 10-30% decrease in material waste and a similar reduction in production delays. This not only saves money but also aligns with sustainability goals, reducing the environmental impact of manufacturing.

Furthermore, custom parts can integrate multiple functions into a single component, reducing the number of parts needed in an assembly. This simplification leads to lower assembly times, decreased complexity in supply chain management, and reduced risk of errors. For example, in the automotive industry, custom engineered brackets that combine several functions have been shown to cut assembly costs by up to 25% and improve overall reliability. By investing in custom design, companies can achieve a leaner, more cost-effective production process.

It's also worth noting that advances in technologies like 3D printing have made prototyping and small-batch production of custom parts more affordable. This allows businesses to test and refine designs without committing to large-scale manufacturing, further mitigating financial risks. In summary, while the upfront investment in custom engineering parts might be higher, the long-term cost benefits through optimized design, reduced waste, and improved efficiency make them a wise choice for enhancing production profitability.

Качество продукции является критическим фактором для поддержания competitive advantage и удовлетворения требований клиентов. Заказные инженерные детали играют pivotal role в обеспечении высочайшего уровня качества и надежности, поскольку они проектируются с учетом exact specifications и operating conditions конкретного применения. В отличие от стандартных деталей, которые могут иметь компромиссы в design для универсальности, custom детали are engineered to perform optimally in their intended environment, leading to fewer failures, higher precision, and enhanced overall product performance.

Take, for example, the aerospace industry, where safety and reliability are paramount. Standard bolts or fasteners might not meet the rigorous demands of aircraft engines, where vibrations, temperature extremes, and stress loads are extreme. By using custom-designed fasteners made from specialized materials and with precise tolerances, aerospace companies can ensure that components withstand these conditions, reducing the risk of in-flight failures. Statistics from the Federal Aviation Administration (FAA) indicate that the adoption of custom parts in critical systems has contributed to a 40% reduction in maintenance-related incidents over the past decade.

In consumer electronics, custom engineering parts allow for better integration and miniaturization. For instance, a smartphone manufacturer might design a custom battery compartment that maximizes space efficiency while improving heat dissipation. This not only enhances the device's performance but also extends its lifespan, leading to higher customer satisfaction and brand loyalty. Studies show that products with custom components have a 20% higher customer satisfaction rate due to improved functionality and durability.

Moreover, custom parts facilitate better quality control during manufacturing. Since they are produced in smaller batches or as per order, manufacturers can implement more stringent inspection processes, catching defects early and ensuring consistency. This is in contrast to mass-produced standard parts, where quality might vary between batches. By partnering with experienced engineering firms, businesses can leverage advanced testing methods, such as non-destructive testing and finite element analysis, to validate the integrity of custom parts before deployment.

Additionally, the ability to use advanced materials in custom design further boosts quality. For example, in the medical device industry, custom implants made from biocompatible materials like titanium or PEEK offer superior performance compared to standard options, reducing rejection rates and improving patient outcomes. Overall, by prioritizing quality through custom engineering, companies can reduce warranty claims, enhance reputation, and drive long-term growth.

В today's dynamic market, production flexibility is essential for responding quickly to changing customer demands, technological advancements, and competitive pressures. Заказные инженерные детали provide unparalleled flexibility, allowing companies to adapt their production processes without major overhauls. This adaptability is crucial for maintaining agility and seizing new opportunities, whether it's launching a new product line, scaling operations, or entering niche markets.

Consider a food processing plant that needs to upgrade its packaging machinery to handle a new product shape. Using standard parts might require purchasing entirely new equipment or making costly modifications. However, with custom engineering, the plant can design and fabricate specific components, such as custom molds or conveyors, that integrate seamlessly with existing machinery. This approach not only saves time and money but also minimizes disruption to production. According to industry surveys, businesses that utilize custom parts report a 30% faster time-to-market for new products compared to those relying solely on standard components.

Custom parts also enable better scalability. As production volumes increase, companies can order custom parts in larger quantities, often benefiting from economies of scale in manufacturing. Conversely, for low-volume or prototype production, technologies like 3D printing allow for cost-effective custom part creation without the need for expensive tooling. This flexibility is particularly valuable for startups and SMEs that need to test ideas before committing to mass production.

Furthermore, custom engineering facilitates innovation by allowing experimentation with new designs and materials. For instance, in the renewable energy sector, custom turbine blades designed for specific wind conditions can significantly increase energy output. By collaborating with engineering experts, companies can iterate quickly on designs, incorporating feedback and improvements in real-time. This iterative process fosters a culture of continuous improvement and keeps businesses at the forefront of their industries.

In summary, the flexibility offered by custom engineering parts empowers companies to stay responsive and innovative. By avoiding the constraints of off-the-shelf solutions, businesses can tailor their production systems to evolving needs, ultimately driving efficiency and growth.

Инновации являются двигателем progress в любой отрасли, и заказные инженерные детали играют key role в ускорении technological advancement. By enabling the creation of components that push the boundaries of what's possible, custom engineering fosters experimentation, prototyping, and the development of cutting-edge products. This is especially important in sectors like robotics, healthcare, and advanced manufacturing, where bespoke solutions are often necessary to achieve breakthrough performance.

For example, in the field of robotics, custom actuators and sensors allow for the design of robots with unique capabilities, such as enhanced dexterity or autonomy. These components are tailored to specific tasks, enabling robots to perform complex operations in environments like manufacturing floors or surgical theaters. Research from institutions like MIT has shown that custom parts in robotics can lead to a 50% improvement in efficiency and functionality compared to using standard off-the-shelf parts.

In healthcare, custom engineering parts are revolutionizing medical devices and implants. Personalized prosthetics or surgical instruments designed from patient-specific data ensure better fit and outcomes. The adoption of additive manufacturing for custom parts has reduced lead times for such devices from weeks to days, accelerating treatment and improving patient care. Statistics indicate that the global market for custom medical parts is growing at over 15% annually, driven by demand for precision and personalization.

Moreover, custom parts facilitate the integration of emerging technologies, such as IoT sensors or AI-driven components, into existing systems. By designing parts that incorporate these technologies, companies can create smart, connected production environments that optimize operations through real-time data analytics. This not only boosts efficiency but also opens new revenue streams through value-added services.

By investing in custom engineering, businesses can position themselves as innovators, attracting talent and investment. The ability to rapidly prototype and deploy custom solutions allows for faster iteration and adaptation to market trends, ensuring long-term competitiveness.

To harness the benefits of custom engineering parts, companies should follow a structured approach. First, conduct a thorough analysis of current production processes to identify areas where standard parts are causing inefficiencies. Engage with engineering partners early in the design phase to ensure that custom parts are feasible and cost-effective. Utilize digital tools like CAD and simulation software to visualize and test designs before manufacturing.

Start with pilot projects to validate the effectiveness of custom parts and scale up gradually. Monitor key performance indicators, such as reduction in downtime, improvement in product quality, and cost savings, to measure ROI. Foster collaboration between design, manufacturing, and supply chain teams to ensure seamless integration.

By taking these steps, businesses can successfully integrate custom engineering parts into their operations, driving significant improvements in production efficiency.

В заключение, заказные инженерные детали offer a powerful means to enhance production efficiency through cost reduction, quality improvement, flexibility, and innovation. By moving beyond standard solutions and embracing customization, companies can achieve sustainable growth and competitive advantage. As technology continues to evolve, the opportunities for custom engineering will only expand, making it an essential strategy for future-proofing production systems. Invest in custom parts today to unlock the full potential of your manufacturing operations.