Что делает литые детали такими прочными и надежными в машиностроении? Это вопрос, который волнует инженеров, производителей и потребителей по всему миру. Литые детали, изготовленные с помощью процессов литья, являются фундаментальными компонентами во множестве машин, от автомобилей до промышленного оборудования. Их способность выдерживать экстремальные нагрузки, высокие температуры и суровые условия эксплуатации делает их незаменимыми. Но как именно достигается эта прочность и надежность? И почему они так важны для современного машиностроения?

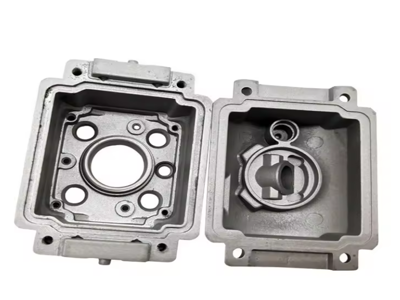

Литые детали производятся путем заливки расплавленного металла или сплава в форму, где он охлаждается и затвердевает, принимая желаемую форму. Этот процесс, известный как литье, существует тысячи лет, но с развитием технологий он стал более точным и эффективным. В машиностроении литые детали используются повсеместно: в двигателях, трансмиссиях, рамах машин и многих других компонентах. Их популярность объясняется способностью создавать сложные геометрии с высокой точностью и при относительно низких затратах. Однако, прочность и надежность этих деталей не являются данностью; они зависят от множества факторов, включая выбор материала, процесс литья и последующую обработку.

Почему прочность так важна? Простая аналогия: представьте двигатель автомобиля. Если литой блок цилиндров не обладает достаточной прочностью, он может треснуть под давлением, что приведет к катастрофическому отказу. То же самое относится к промышленным машинам, где отказ компонента может вызвать простои производства, финансовые потери и даже угрозу безопасности. Надежность, с другой стороны, относится к способности детали выполнять свои функции в течение длительного времени без сбоев. В машиностроении, где машины часто работают непрерывно в тяжелых условиях, надежность является ключевым параметром для минимизации обслуживания и максимизации срока службы.

Но как мы измеряем прочность и надежность? И что можно сделать для их улучшения? Эти вопросы подводят нас к более глубокому обсуждению материалов, процессов и инноваций в области литья.

Выбор материала является первым и, возможно, самым важным шагом в обеспечении прочности литых деталей. Разные материалы обладают разными механическими свойствами, такими как предел прочности, ударная вязкость и устойчивость к износу. В машиностроении commonly используются стали, чугуны, алюминиевые сплавы и другие металлы. Например, чугун известен своей excellent прочностью на сжатие и износостойкостью, что делает его идеальным для деталей, подвергающихся высоким нагрузкам, таких как коленчатые валы или корпуса редукторов. Алюминиевые сплавы, с другой стороны, легче и обладают good коррозионной стойкостью, но могут require дополнительного упрочнения для достижения высокой прочности.

Что определяет прочность материала? Микроструктура металла играет crucial роль. During литья, кристаллическая структура формируется по мере охлаждения расплава. Defects, such as porosity или inclusions, могут ослабить деталь. Therefore, контроль процесса литья essential для минимизации этих defects. Additionally, термическая обработка, такая as закалка и отпуск, может significantly улучшить прочность путем изменения микроструктуры. For instance, закалка стали увеличивает ее твердость и прочность, но может сделать ее хрупкой; отпуск затем reduces хрупкость, balancing прочность и toughness.

Но is ли просто выбрать прочный материал enough? Не обязательно. Прочность also зависит от геометрии детали и loads, которые она испытывает. Stress концентраторы, такие as резкие изменения сечения или отверстия, могут lead к локальным напряжениям, превышающим предел прочности material. Поэтому инженеры используют computer-aided design (CAD) и finite element analysis (FEA) для моделирования напряжений и оптимизации designs. Это позволяет predict weak points и modify дизайн до производства, enhancing overall прочность.

Moreover, innovations в materials science continuously push boundaries. Nanocomposites и advanced сплавы offer higher прочность-to-weight ratios, making them attractive для aerospace и automotive applications. Однако, их adoption в литье requires development новых processes, таких как литье под давлением с ceramic molds или additive manufacturing techniques. Вопрос then becomes: как эти новые materials integrate into traditional литье processes без compromising reliability?

In summary, material selection is a complex interplay of properties, processing, and design. To achieve high прочность, one must consider not only the inherent strength of the material but also how it is processed and shaped. This leads us to the next aspect: the casting process itself.

Процесс литья directly impacts the reliability of cast parts. Different casting methods, such as sand casting, investment casting, die casting, and others, offer varying levels of precision, surface finish, and mechanical properties. Sand casting, for example, is economical and suitable for large parts but may produce rougher surfaces and more defects. Investment casting, on the other hand, allows for high precision and smooth finishes but is more expensive and time-consuming. The choice of process depends on the application requirements, including the desired reliability.

How does the casting process affect reliability? Defects like shrinkage porosity, gas porosity, and inclusions can originate during casting and act as stress raisers, reducing the fatigue life and overall reliability of the part. To mitigate these issues, process parameters such as pouring temperature, cooling rate, and mold design must be carefully controlled. For instance, in die casting, high pressure is used to fill the mold quickly, reducing porosity but potentially introducing other defects if not managed properly. Simulation software, such as casting simulation tools, helps predict and optimize these parameters before actual production, thereby enhancing reliability.

But reliability is not just about avoiding defects; it's also about consistency. In mass production, variations in the casting process can lead to part-to-part inconsistencies, affecting reliability. Statistical process control (SPC) and quality assurance measures are employed to monitor and maintain consistency. For example, non-destructive testing (NDT) methods like X-ray or ultrasonic testing are used to inspect cast parts for internal defects without damaging them. This ensures that only parts meeting reliability standards are used in critical applications.

Furthermore, post-casting treatments play a role in reliability. Heat treatment, as mentioned earlier, can improve mechanical properties, but it must be done correctly to avoid introducing new defects. Machining and surface finishing can also affect reliability by removing surface irregularities that might initiate cracks. In some cases, coatings or surface treatments are applied to enhance corrosion resistance or wear resistance, further boosting long-term reliability.

Looking ahead, advancements in automation and Industry 4.0 are transforming casting processes. Smart foundries use sensors and IoT devices to monitor processes in real-time, allowing for immediate adjustments and predictive maintenance. This not only improves efficiency but also enhances reliability by reducing human error and variability. However, these technologies require significant investment and expertise, raising questions about accessibility for smaller manufacturers.

In essence, the casting process is a critical factor in achieving reliable cast parts. By optimizing processes, controlling parameters, and employing advanced technologies, manufacturers can produce parts that perform consistently over time. But how do we test and verify this reliability? That brings us to the next section.

Testing and quality control are essential to ensure that cast parts meet the required standards of strength and reliability. Various methods are used, from destructive testing to non-destructive evaluation. Destructive testing, such as tensile tests or impact tests, involves breaking samples to measure mechanical properties like ultimate tensile strength, yield strength, and toughness. While this provides accurate data, it destroys the part, so it is typically done on representative samples from a batch.

Non-destructive testing (NDT) methods, on the other hand, allow for inspection without damage. Techniques like ultrasonic testing, radiography (X-ray), and magnetic particle inspection are commonly used to detect internal and surface defects. For example, ultrasonic testing uses sound waves to identify discontinuities within the material, making it ideal for thick sections. These methods are crucial for quality assurance in critical applications, such as aerospace or automotive components, where failure could have severe consequences.

But testing alone is not enough; it must be integrated into a comprehensive quality management system. Standards like ISO 9001 provide frameworks for ensuring consistent quality throughout the production process. Statistical analysis of test data helps identify trends and potential issues early, allowing for corrective actions. For instance, if a batch of parts shows higher porosity, the casting process can be adjusted to prevent recurrence.

Reliability testing goes beyond initial quality checks; it involves assessing how parts perform over time under realistic conditions. Fatigue testing, for example, subjects parts to cyclic loading to simulate long-term use and determine their fatigue life. Accelerated life testing might be used to predict reliability in a shorter time frame. These tests are vital for designing parts that can withstand the rigors of actual operation.

Moreover, with the advent of digital twins and simulation, virtual testing is becoming more prevalent. Finite element analysis (FEA) can simulate stresses and predict failure modes without physical prototypes, saving time and resources. However, physical validation is still necessary to confirm simulation results, especially for new materials or designs.

In summary, a robust testing and quality control regimen is key to ensuring the reliability of cast parts. By combining destructive and non-destructive methods, adhering to standards, and leveraging technology, manufacturers can deliver parts that are both strong and dependable. But what does the future hold for cast parts in machinery? Let's explore emerging trends and challenges.

The future of cast parts in machinery is shaped by trends such as lightweighting, sustainability, and digitalization. Lightweighting, driven by demands for fuel efficiency in automotive and aerospace sectors, is pushing the development of high-strength, lightweight materials like magnesium alloys or composites. However, casting these materials presents challenges, such as higher costs and process complexities. Sustainability is another key trend, with a focus on reducing energy consumption, waste, and environmental impact in foundries. Recycling of materials and adoption of green technologies are becoming increasingly important.

Digitalization, including additive manufacturing (3D printing), is revolutionizing casting. Additive manufacturing allows for the production of complex geometries that are difficult or impossible with traditional casting, potentially enhancing strength and reliability by optimizing designs. For example, lattice structures can reduce weight while maintaining strength. However, the reliability of additively manufactured parts is still under research, and integration with existing processes requires careful consideration.

Challenges remain, such as the high cost of advanced materials and technologies, which may limit adoption in cost-sensitive industries. Additionally, as machines become more automated and connected, the reliability of cast parts must keep pace with higher performance demands. Education and training are crucial to equip the workforce with skills needed for these advancements.

In conclusion, while cast parts continue to be vital in machinery, ongoing innovation and attention to quality are essential to maintain their strength and reliability. By embracing new materials, processes, and technologies, the industry can meet future challenges and opportunities.

This article has explored the multifaceted aspects of strength and reliability in cast parts, from materials and processes to testing and future trends. It highlights that achieving high performance requires a holistic approach, combining traditional knowledge with modern innovations. As machinery evolves, so too must our methods for ensuring that cast parts remain robust and dependable.