В современном мире промышленности и производства, где каждый процент эффективности может стать решающим фактором успеха, гравитационное литьё emerges as a key technology that bridges the gap between traditional methods and cutting-edge innovation. This process, which harnesses the natural force of gravity to fill molds with molten metal, offers unparalleled advantages in terms of precision, cost-effectiveness, and sustainability. As industries evolve and demand for high-quality components grows, our services in gravitational casting provide a robust solution tailored to meet the highest standards of excellence. In this comprehensive article, we delve deep into the nuances of gravitational casting, exploring its history, technological advancements, applications across sectors, and why choosing our top-tier services can revolutionize your production line. From automotive to aerospace, and from small-scale artisans to large industrial giants, gravitational casting is not just a method—it's a strategic asset for achieving manufacturing supremacy.

Гравитационное литьё, или литьё под действием силы тяжести, has roots that trace back to ancient civilizations, where early metalworkers utilized simple gravity-fed techniques to create tools and artifacts. However, it wasn't until the Industrial Revolution that this method began to be systematized and refined. In the 19th century, advancements in metallurgy and mold-making allowed for more precise control over the casting process, leading to the development of standardized practices. The 20th century saw further innovations, with the introduction of automated systems and computer-aided design (CAD) that enhanced accuracy and repeatability. Today, gravitational casting stands as a mature yet dynamic technology, continuously evolving with the integration of digital tools, robotics, and sustainable practices. Our services build upon this rich heritage, incorporating state-of-the-art equipment and expert knowledge to deliver results that exceed expectations. By understanding this historical context, we can appreciate how gravitational casting has become a cornerstone of modern manufacturing, offering a blend of tradition and innovation that is hard to match.

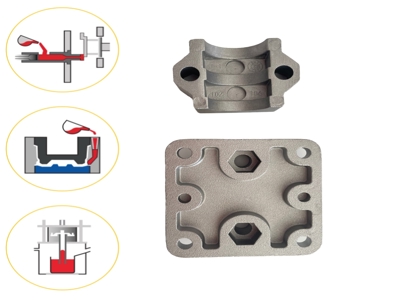

At its core, gravitational casting involves pouring molten metal into a mold cavity under the influence of gravity alone, without external pressure or vacuum assistance. This simplicity is one of its greatest strengths, as it reduces complexity and minimizes energy consumption. The process typically begins with the preparation of a mold, which can be made from materials such as sand, ceramic, or metal, depending on the application and desired finish. Molten metal, often aluminum, zinc, or copper alloys, is then ladled or poured into the mold, where it flows naturally to fill all intricate details. Key advantages include excellent surface finish, minimal porosity, and the ability to produce complex geometries with tight tolerances. Our services leverage advanced simulation software to optimize mold design and pouring parameters, ensuring that every cast component meets stringent quality standards. Additionally, we employ rigorous quality control measures, including non-destructive testing and metallurgical analysis, to guarantee durability and performance. This technological prowess allows us to offer gravitational casting services that are not only efficient but also highly reliable, making them ideal for critical applications in industries such as automotive, aerospace, and medical devices.

Choosing gravitational casting for your production needs brings a host of benefits that can significantly enhance operational efficiency and product quality. Firstly, it is a cost-effective method, as it requires less energy and equipment compared to high-pressure die casting or other aggressive techniques. This translates to lower operational costs and a smaller environmental footprint, aligning with modern sustainability goals. Secondly, gravitational casting produces components with superior mechanical properties, such as high strength and excellent corrosion resistance, due to the slow and controlled solidification process. This makes it suitable for parts that must withstand harsh conditions, like engine blocks or structural elements. Moreover, the flexibility in design allows for the creation of intricate shapes and thin walls that might be challenging with other methods. Our services amplify these advantages by offering customization options, rapid prototyping, and scalable production runs. Whether you're a startup looking to minimize initial investment or an established company seeking to optimize existing processes, our gravitational casting solutions provide a competitive edge that can lead to increased market share and customer satisfaction.

Gravitational casting finds applications across a wide spectrum of industries, each benefiting from its unique attributes. In the automotive sector, it is used to manufacture engine components, transmission parts, and lightweight structures that contribute to fuel efficiency and performance. The aerospace industry relies on gravitational casting for critical components like turbine blades and landing gear parts, where precision and reliability are paramount. In the consumer goods sector, it enables the production of high-quality items such as cookware, hardware, and decorative elements. The medical field utilizes this technology for surgical instruments and implantable devices, thanks to its ability to produce biocompatible materials with exacting specifications. Our services cater to所有这些 отраслей, offering tailored solutions that address specific challenges and requirements. By partnering with us, you gain access to expertise that spans multiple domains, ensuring that your gravitational casting projects are executed with the highest level of professionalism and attention to detail. This versatility makes gravitational casting an indispensable tool for innovation and growth in today's competitive landscape.

The future of gravitational casting is bright, driven by continuous innovations that enhance its capabilities and expand its applications. Emerging trends include the integration of additive manufacturing for mold creation, which allows for even greater design freedom and faster turnaround times. Advances in material science are leading to the development of new alloys with improved properties, such as higher temperature resistance or enhanced recyclability. Additionally, the adoption of Industry 4.0 technologies, such as IoT sensors and AI-driven analytics, is transforming gravitational casting into a smart, data-rich process that optimizes efficiency and reduces waste. Our services are at the forefront of these developments, investing in research and development to stay ahead of the curve. We are committed to sustainability, exploring ways to minimize resource consumption and promote circular economy principles. By choosing our gravitational casting services, you are not only investing in a proven technology but also positioning your production for future advancements. This forward-thinking approach ensures that your business remains agile and responsive to changing market demands, securing long-term success in an ever-evolving industrial environment.

When it comes to gravitational casting, not all service providers are created equal. Our company stands out due to our unwavering commitment to quality, innovation, and customer satisfaction. We boast a team of experienced engineers and technicians who bring decades of expertise to every project, ensuring that each cast component is produced to the highest standards. Our state-of-the-art facilities are equipped with the latest technology, from advanced melting furnaces to precision CNC machines for finishing operations. We offer comprehensive support throughout the entire process, from initial design consultation to post-production services like machining and assembly. Our competitive pricing and flexible terms make our services accessible to businesses of all sizes, while our rigorous quality assurance protocols guarantee that you receive products that meet or exceed industry benchmarks. Testimonials from satisfied clients across various industries attest to our reliability and excellence. By partnering with us, you gain a trusted ally dedicated to helping you achieve your production goals with efficiency and precision. In a world where quality can make or break a business, our gravitational casting services provide the assurance you need to succeed.

In summary, gravitational casting is a powerful and versatile manufacturing technique that offers numerous benefits for modern production. From its historical roots to its future potential, this method embodies a perfect blend of simplicity and sophistication. Our services elevate gravitational casting to new heights, delivering unmatched quality, innovation, and value. Whether you are looking to reduce costs, improve product performance, or explore new design possibilities, we have the expertise and resources to make it happen. Don't settle for mediocre results—choose our gravitational casting services and experience the difference that top-tier quality can make. Contact us today to discuss your project needs and discover how we can help transform your production processes for the better. Together, we can build a future where excellence is the standard, and innovation knows no bounds.