В современном промышленном мире металлообработка играет ключевую роль в создании бесчисленных продуктов, от автомобильных деталей до медицинского оборудования. Среди множества технологий обработки металла CNC (Computer Numerical Control) фрезерование выделяется как одна из самых передовых и эффективных методик. Но что делает её такой особенной? Какие конкретные преимущества она предлагает предприятиям и инженерам? В этой статье мы глубоко погрузимся в мир CNC фрезерования, исследуя его сильные стороны через призму практики, данных и экспертных мнений. Мы ответим на эти вопросы, предоставив исчерпывающий обзор, который поможет вам понять, почему CNC фрезерование стало неотъемлемой частью современного производства.

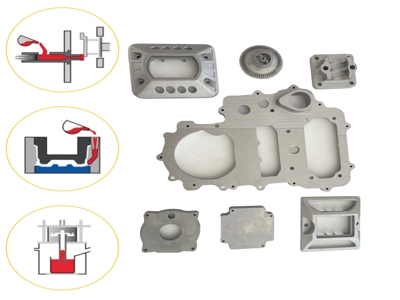

CNC фрезерование — это процесс, в котором компьютер управляет движением фрезы для удаления материала с заготовки, создавая сложные формы и детали с высокой точностью. Эта технология зародилась в середине XX века и с тех пор эволюционировала, интегрируя цифровые системы и программное обеспечение. Основные компоненты включают CNC станок, который состоит из шпинделя, стола для закрепления заготовки, и системы управления, основанной на G-кодах. Эти коды, генерируемые из CAD (Computer-Aided Design) моделей, инструктируют станок о траектории движения, скорости вращения и других параметрах. Прелесть CNC в его универсальности: он может обрабатывать различные металлы, такие как сталь, алюминий, титан, и даже сплавы, предлагая решения для широкого спектра отраслей, включая аэрокосмическую, автомобильную и электронную промышленности.

Исторически, фрезерование было ручным процессом, требующим высокого мастерства оператора, но с adventом CNC, оно стало автоматизированным, снизив человеческую ошибку и увеличив repeatability. Например, в 1950-х годах первые CNC машины использовались в военной промышленности для производства сложных компонентов, и с тех пор технология непрерывно улучшалась. Сегодня, с интеграцией IoT (Internet of Things) и AI (Artificial Intelligence), CNC фрезерование достигло невероятных уровней точности и efficiency, делая его indispensable для high-volume production и prototyping.

Но почему именно CNC фрезерование? Ответ lies в его inherent преимуществах, которые мы рассмотрим подробно. От точности до cost-effectiveness, каждый аспект contributes к его popularity. В следующих разделах, мы разберем эти преимущества step by step, используя реальные примеры и статистику, чтобы подкрепить наши утверждения. Например, according к данным от ассоциаций như SME (Society of Manufacturing Engineers), adoption CNC технологий увеличило productivity в metalworking на up to 50% за последнее десятилетие. Это лишь верхушка iceberg; давайте копать глубже.

Одним из самых значительных преимуществ CNC фрезерования является его способность достигать исключительной точности и повторяемости. В metalworking, где допуски often измеряются в микронах, даже minor deviations могут lead к failure конечного продукта. CNC machines, управляемые компьютерами, могут maintain точность до 0.001 mm или better, depending от модели станка и calibration. Это означает, что детали, произведенные с помощью CNC, идеально соответствуют design specifications, reducing scrap rates и improving overall quality.

Повторяемость — это ability производить identical детали batch after batch без variation. В традиционном фрезеровании, human factor introduces inconsistencies, но CNC eliminates это благодаря digital control. For instance, в automotive industry, где engines require precise components, CNC фрезерование ensures что каждый piston или valve изготовлен с identical dimensions, leading к improved performance и longevity. Исследования показывают, что CNC machines can achieve repeatability с coefficient вариации менее 0.1%, compared к 2-5% для manual methods, согласно отчетам от институтов как NIST (National Institute of Standards and Technology).

Пример из практики: Компания Boeing использует CNC фрезерование для производства крыльев самолетов, где точность критична для aerodynamic efficiency. Благодаря CNC, они могут создавать complex curves и holes с tolerances within 0.025 mm, что невозможно достичь manually. Это not only enhances safety но и reduces weight, contributing к fuel efficiency. Таким образом, высокая точность и повторяемость делают CNC фрезерование ideal для applications, требующих perfection, such как medical implants или aerospace components.

Автоматизация — это сердце CNC фрезерования, offering substantial gains в productivity. By automating the milling process, companies can operate machines 24/7 with minimal human intervention, leading to higher output rates and reduced labor costs. CNC systems can be programmed to run unattended for hours or even days, especially with advanced features like tool changers and pallet systems that allow for continuous operation. This is particularly beneficial for high-volume production, where speed and consistency are paramount.

In terms of productivity, CNC milling can significantly reduce cycle times compared to manual methods. For example, a complex part that might take hours to mill manually can be produced in minutes with CNC, thanks to optimized tool paths and high spindle speeds. Data from industry surveys indicate that CNC automation can increase production throughput by up to 300%, depending on the application. Moreover, with the integration of CAD/CAM software, the entire process from design to manufacturing is streamlined, reducing lead times and enabling faster time-to-market for new products.

A real-world example is the manufacturing of smartphone casings. Companies like Apple use CNC milling to produce aluminum frames with intricate designs at high speeds. By automating the process, they can meet massive demand while maintaining quality. Additionally, CNC machines can be networked into smart factories, where data analytics and predictive maintenance further boost efficiency. For instance, sensors on CNC mills can monitor tool wear and automatically schedule replacements, preventing downtime and ensuring continuous operation. This level of automation not only enhances productivity but also makes manufacturing more resilient to disruptions, such as labor shortages.

CNC фрезерование offers remarkable flexibility, allowing for the production of a wide variety of parts without the need for extensive retooling. With simple software changes, the same CNC machine can switch from milling one design to another, making it ideal for both mass production and custom jobs. This versatility is crucial in today's market, where consumer demands are constantly evolving, and batch sizes are becoming smaller due to trends like mass customization.

The ability to work with diverse materials is another aspect of this flexibility. CNC mills can handle metals ranging from soft aluminum to hard steels and exotic alloys, as well as non-metallic materials like plastics and composites. This makes them suitable for multiple industries; for example, in the medical field, CNC is used to mill titanium for implants, while in jewelry, it crafts intricate designs from precious metals. The use of multi-axis CNC machines (e.g., 5-axis milling) further enhances versatility by enabling complex geometries and undercuts that are impossible with traditional 3-axis milling.

Consider the case of prototyping: Startups and R&D departments rely on CNC milling for rapid prototyping because it allows quick iterations based on feedback. By uploading a new CAD file, they can produce a revised part in hours, accelerating innovation. Statistics show that companies using CNC for prototyping reduce development time by up to 40% compared to manual methods, as per reports from engineering forums. This flexibility not only supports innovation but also helps businesses adapt to market changes quickly, giving them a competitive edge.

Хотя initial investment в CNC оборудование может быть high, долгосрочная economic efficiency значительна. By reducing labor costs, minimizing material waste, and decreasing error rates, CNC milling leads to lower per-unit costs over time. Automation means fewer operators are needed, and those required can focus on programming and supervision rather than manual labor, leading to savings in wages and training. Additionally, the high precision of CNC reduces scrap rates; for instance, in metalworking, scrap can account for up to 10% of material costs in manual processes, but CNC can cut this to below 2%.

Energy efficiency is another cost-saving factor. Modern CNC machines are designed to consume less power while maintaining high performance, and features like regenerative braking can recover energy during deceleration. According to energy audits, CNC mills can be up to 20% more energy-efficient than older manual machines, contributing to lower operational expenses. Furthermore, the ability to produce parts faster means higher throughput, which spreads fixed costs over more units, improving overall profitability.

A practical example is in the automotive sector: Major manufacturers like Toyota have integrated CNC milling into their production lines, reporting cost reductions of 15-20% due to reduced waste and increased automation. By using CNC for engine blocks and transmission parts, they achieve better material utilization and faster production cycles. This economic advantage makes CNC milling accessible not only to large corporations but also to small and medium-sized enterprises (SMEs) through outsourcing services, where companies can hire CNC milling without upfront investment, further democratizing advanced manufacturing.

CNC фрезерование значительно enhances quality control through consistent and precise manufacturing. The digital nature of CNC allows for real-time monitoring and adjustments, ensuring that each part meets strict quality standards. Integrated sensors and probes can measure dimensions during milling, automatically compensating for tool wear or thermal expansion, which is common in metalworking. This proactive approach reduces defects and ensures that products are reliable and safe for end-use.

In industries where quality is non-negotiable, such as aerospace or medical devices, CNC milling is indispensable. For example, in the production of surgical instruments, even micron-level imperfections can lead to failures, but CNC ensures that every cut is exact. Quality management systems (QMS) like ISO 9001 are easily integrated with CNC processes, as data from machines can be logged and analyzed for continuous improvement. Studies show that companies adopting CNC report a 30% reduction in quality-related issues, according to quality assurance surveys.

Moreover, CNC enables better surface finishes and tighter tolerances, which are critical for functional parts like gears or bearings. By using advanced tooling and cooling systems, CNC mills can achieve surface roughness values as low as Ra 0.4 μm, compared to Ra 1.6 μm or higher for manual milling. This not only improves the aesthetic appeal but also enhances performance, such as reducing friction in moving parts. Thus, the superior quality control offered by CNC milling translates to higher customer satisfaction and fewer returns, strengthening brand reputation.

CNC фрезерование contributes to a safer working environment by minimizing direct human interaction with dangerous machinery. In manual milling, operators are exposed to risks like flying chips, sharp tools, and repetitive strain injuries, but CNC enclosures and automation reduce these hazards. Safety features such as emergency stops, light curtains, and automated tool handling ensure that accidents are rare, making CNC mills compliant with occupational safety standards like OSHA guidelines.

<From an environmental perspective, CNC milling is more sustainable than traditional methods. The precision of CNC reduces material waste, as less raw metal is needed due to accurate cuts. Additionally, modern CNC machines often incorporate eco-friendly technologies, such as coolant recycling systems and energy-efficient motors, which lower the carbon footprint. For instance, some advanced mills use minimum quantity lubrication (MQL) instead of flood cooling, reducing fluid consumption and waste disposal issues. Data indicates that CNC milling can decrease material waste by up to 30% and energy use by 15% compared to conventional milling, aligning with green manufacturing initiatives.

An example of this is in the packaging industry: Companies use CNC to mill molds for plastic injection, where reduced waste translates to less environmental impact. By adopting CNC, businesses not only protect their workers but also contribute to corporate social responsibility (CSR) goals, appealing to environmentally conscious consumers. This dual benefit of safety and sustainability makes CNC milling a forward-thinking choice for modern factories.

CNC фрезерование seamlessly integrates with other advanced technologies, enhancing its capabilities and future-proofing manufacturing processes. The adoption of Industry 4.0 principles allows CNC mills to be part of interconnected smart factories, where data from machines is used for predictive maintenance, optimization, and real-time decision-making. For example, IoT sensors can monitor machine health and alert operators to potential issues before they cause downtime, improving overall equipment effectiveness (OEE).

Artificial intelligence (AI) and machine learning are also being incorporated into CNC systems. AI algorithms can optimize tool paths for maximum efficiency, predict tool life, and even adapt to variations in material properties during milling. This leads to further reductions in cycle times and costs. Additionally, additive manufacturing (3D printing) is often combined with CNC milling in hybrid machines, allowing for the creation of complex parts that combine additive and subtractive processes. This integration expands the possibilities for design and manufacturing, particularly in fields like aerospace where lightweight structures are essential.

Cloud computing enables remote programming and monitoring of CNC mills, facilitating global collaboration and flexible manufacturing. For instance, a designer in one country can upload a CAD file to a cloud-based CAM system, and a CNC mill in another location can produce the part instantly. This connectivity reduces barriers to entry and supports distributed manufacturing models. As technology evolves, CNC milling will continue to benefit from innovations such as digital twins and augmented reality for training and maintenance, ensuring it remains at the forefront of industrial advancement.

To illustrate the advantages of CNC milling, let's explore some real-world case studies. In the automotive industry, Tesla uses CNC milling for prototyping and production of electric vehicle components. By employing multi-axis CNC machines, they achieve complex shapes for battery enclosures and motor parts with high precision, reducing development time and costs. This has enabled Tesla to iterate quickly and maintain a competitive edge in the fast-evolving EV market.

Another example is in the medical sector: Zimmer Biomet, a leading manufacturer of orthopedic implants, relies on CNC milling to produce custom knee and hip replacements. The high accuracy ensures perfect fit for patients, improving surgical outcomes. Through CNC, they can work with biocompatible materials like titanium and cobalt-chromium alloys, producing implants that last longer and reduce revision rates. Data from clinical studies show that CNC-milled implants have a success rate of over 95%, compared to 85% for traditionally manufactured ones.

In consumer electronics, companies like Samsung use CNC milling for smartphone frames and components. The ability to mill aluminum and glass with tight tolerances allows for sleek designs and durable products. By automating the process, they scale production to meet global demand while maintaining consistency. These examples demonstrate how CNC milling drives innovation and efficiency across various sectors, providing tangible benefits that translate to business success.

В заключение, услуга CNC фрезерования offers a multitude of advantages that make it indispensable for modern metalworking. From unmatched precision and repeatability to automation, flexibility, cost savings, and enhanced quality control, CNC milling addresses the core challenges of manufacturing in the 21st century. Its integration with cutting-edge technologies like AI and IoT ensures that it will continue to evolve, offering even greater benefits in the future.

Businesses that adopt CNC milling can expect improved productivity, reduced costs, and higher product quality, giving them a competitive advantage in a global market. Whether you're involved in aerospace, automotive, medical, or any other industry, leveraging CNC milling can transform your operations and drive innovation. As we've seen through examples and data, the benefits are clear and compelling.

So, если вы рассматриваете outsourcing или investing в CNC оборудование, now is the time to act. Embrace эту технологию чтобы unlock новые возможности и ensure что ваше производство remains на переднем edge. CNC фрезерование — это не просто инструмент; это catalyst для progress в metalworking.