Вы когда-нибудь задумывались, что делает упаковку идеальной для вашего продукта? В мире, где конкуренция на рынке упаковки растет с каждым днем, выбор правильного материала может стать решающим фактором успеха. Алюминиевые крышки – это не просто функциональный элемент, а стратегическое решение, которое сочетает в себе легкость, прочность и эстетику. Но почему они так популярны? Как они влияют на сохранность продукта? И действительно ли они экологичны? В этой статье мы подробно разберем эти и многие другие вопросы, чтобы помочь вам сделать осознанный выбор для вашего бизнеса.

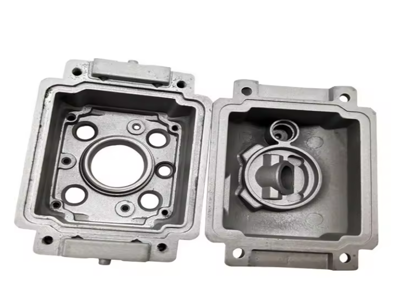

Алюминиевые крышки – это крышки, изготовленные из алюминия или его сплавов, которые используются для герметизации различных контейнеров, таких как банки, бутылки или упаковки для пищевых продуктов, косметики и фармацевтики. Процесс производства начинается с добычи бокситовой руды, которая затем перерабатывается в глинозем, а далее в чистый алюминий через электролиз. Этот металл известен своей легкостью – его плотность составляет около 2,7 г/см³, что делает его идеальным для упаковки, где вес играет crucialную роль в логистике и cost-efficiency. Но как именно алюминий превращается в крышку? Производство включает этапы прокатки листового алюминия, штамповки, нанесения покрытий (например, лака или полимеров для защиты от коррозии) и добавления уплотнительных элементов. Этот процесс обеспечивает высокую точность и customization, позволяя создавать крышки различных размеров и дизайнов. Интересно, что алюминий можно easily recycled, что снижает environmental impact. Однако, вызывает ли это вопросы о долговечности? Давайте explore дальше.

Легкость алюминиевых крышек – одно из их ключевых преимуществ. По сравнению с alternatives, такими как сталь или пластик, алюминий имеет significantly lower weight, что directly translates в reduced transportation costs. Например, при перевозке large quantities упаковки, even small weight savings can lead to substantial fuel savings и lower carbon emissions. Это особенно важно в era sustainability, где компании стремятся minimize their ecological footprint. Но как именно это works? Представьте, что вы shipping 1000 units продукта: если каждая крышка весит на 10 grams меньше благодаря алюминию, общая economy веса составит 10 kg, что может reduce fuel consumption на several percentages. Кроме того, легкость упрощает handling и хранение, making it easier для работников на production lines. Однако, не sacrifice ли это прочность? Вовсе нет – алюминий обладает excellent strength-to-weight ratio, meaning it can withstand mechanical stresses without adding unnecessary bulk. Это делает его ideal для applications, где weight matters, such as aerospace или automotive industries, но applied к упаковке. Но как насчет durability? Let's dive into that.

Прочность алюминиевых крышек обусловлена их ability to resist deformation, corrosion, and impact. Алюминий naturally forms a protective oxide layer when exposed to air, which prevents rust and degradation, unlike iron-based materials. This innate corrosion resistance makes it suitable for packaging moist or acidic products, such as foods or chemicals, where other materials might fail. Additionally, aluminum can be alloyed with other elements like magnesium or silicon to enhance its mechanical properties, resulting in крышки that can endure high pressures during sealing and transportation. For instance, in the beverage industry, aluminum caps are designed to maintain a tight seal under carbonation pressure, ensuring that drinks remain fizzy and fresh. But how does this translate to real-world scenarios? Consider a can of soda: the aluminum lid must not only be easy to open but also robust enough to prevent leaks or contamination. Tests show that aluminum caps can withstand forces up to several Newtons without cracking, thanks to their ductility and tensile strength. Moreover, they provide excellent barrier properties against light, oxygen, and moisture, which are critical for preserving product quality and shelf life. This is why many pharmaceuticals use aluminum blister packs – to protect sensitive medications from environmental factors. But is there a trade-off? Perhaps in terms of cost or recyclability? Let's examine that next.

Экологичность алюминиевых крышек – горячая тема в contemporary packaging debates. Алюминий is highly recyclable; in fact, it can be recycled indefinitely without loss of quality, which significantly reduces waste and energy consumption compared to virgin production. Recycling aluminum saves up to 95% of the energy required to produce new aluminum from ore, making it a cornerstone of circular economy initiatives. Many countries have established recycling programs where aluminum packaging is collected and reprocessed efficiently. However, critics argue that the initial production of aluminum is energy-intensive due to the electrolysis process, which relies on electricity often generated from fossil fuels. This raises questions about the overall carbon footprint. To address this, manufacturers are increasingly using renewable energy sources and improving efficiency in production. Additionally, aluminum's lightweight nature contributes to lower emissions during transportation, as discussed earlier. But what about end-of-life? Aluminum caps are easy to separate and recycle, unlike some plastics that may contaminate recycling streams. In terms of biodegradability, aluminum does not decompose, but its recyclability offsets this issue. So, while it's not perfect, aluminum offers a sustainable option when managed properly. How does this compare to other materials? Let's explore alternatives.

В мире упаковки, алюминиевые крышки конкурируют с various alternatives, such as plastic caps, steel lids, or even biodegradable options. Plastic caps, often made from PET or PP, are lightweight and cheap but can be less durable and prone to leaching chemicals, especially under heat or UV exposure. They also contribute significantly to plastic pollution, as many are not recycled effectively. Steel lids, on the other hand, are very strong and recyclable but are heavier and more expensive, increasing logistics costs and environmental impact from transportation. Biodegradable materials, like PLA or paper-based options, are emerging but often lack the barrier properties and strength needed for many applications, and their production can have its own environmental drawbacks. Aluminum strikes a balance: it is lighter than steel, more durable than plastic, and highly recyclable. For example, in the food industry, aluminum caps are preferred for their ability to maintain freshness without altering taste, whereas plastic might impart odors. Moreover, aluminum's malleability allows for innovative designs and easy opening features, enhancing user experience. But is cost a factor? Initially, aluminum might be more expensive than plastic, but long-term savings from reduced weight and recyclability can offset this. Ultimately, the choice depends on specific product needs, but aluminum often emerges as a superior option for those prioritizing performance and sustainability. How can businesses implement this? Let's look at practical applications.

Алюминиевые крышки находят применение в diverse industries due to their versatility. In the food and beverage sector, they are used for sealing jars, bottles, and cans containing everything from soft drinks and beers to sauces and preserves. Their ability to provide an airtight seal helps prevent spoilage and maintain flavor. In cosmetics, aluminum caps are popular for packaging creams, lotions, and perfumes, where aesthetics and protection from light are crucial. The pharmaceutical industry relies on aluminum for blister packs and bottle caps to ensure drug integrity and safety. Even in non-food areas, such as industrial chemicals or household products, aluminum caps offer reliable containment. The application process typically involves automation: machines cap containers at high speeds, with aluminum's consistency ensuring minimal defects. For instance, in bottling plants, capping machines can handle thousands of units per hour, thanks to aluminum's ease of processing. Additionally, customization is key – aluminum can be anodized or painted in various colors and finishes to match brand identity. This flexibility makes it a go-to choice for marketers looking to enhance product appeal. But what about challenges? Issues like metal fatigue or compatibility with certain products (e.g., highly acidic substances) must be considered, but these are often mitigated through alloy selection and coatings. Overall, the widespread use underscores aluminum's reliability. How to choose the right type? Let's discuss selection criteria.

Выбор алюминиевых крышек depends on several factors: product type, container material, storage conditions, and budget. First, consider the product's characteristics – is it liquid, solid, acidic, or sensitive to light? For liquids, a tight seal is essential to prevent leaks, so opt for caps with integrated liners or gaskets. For acidic products, ensure the aluminum is coated to resist corrosion. Second, match the cap to the container – aluminum works well with glass, plastic, or metal containers, but the threading and size must be compatible to avoid leaks. Third, evaluate storage conditions: if the product will be exposed to high temperatures or humidity, choose alloys with enhanced resistance. Budget-wise, while aluminum might have a higher upfront cost than plastic, calculate total cost of ownership including transportation, recycling benefits, and product protection. It's also wise to consult with suppliers who can provide samples and conduct tests for specific applications. For example, in the beer industry, twist-off aluminum caps are designed for easy opening while maintaining carbonation. Additionally, consider sustainability goals – if your brand emphasizes eco-friendliness, aluminum's recyclability is a strong selling point. Ultimately, a trial period with small batches can help assess performance before full-scale adoption. But what about future trends? Let's gaze into the crystal ball.

Будущее алюминиевых крышек looks promising with ongoing innovations aimed at enhancing sustainability, functionality, and smart features. One trend is the development of thinner yet stronger aluminum alloys through advanced metallurgy, reducing material use without compromising performance. This aligns with circular economy principles by minimizing waste. Another innovation is the integration of smart technologies, such as QR codes or NFC chips embedded in caps, enabling traceability, authenticity verification, or interactive consumer experiences – imagine scanning a cap to get recipe ideas or product information! Additionally, there is a push towards using more recycled content in production, with some companies aiming for 100% recycled aluminum caps to lower environmental impact. In terms of design, we see trends towards easier-opening mechanisms, like pull-tabs or child-resistant features, catering to convenience and safety. Furthermore, as regulations on single-use plastics tighten globally, aluminum is poised to gain market share as a sustainable alternative. However, challenges remain, such as improving recycling infrastructure and addressing energy costs in production. Collaborations between industries and governments are key to driving these advancements. For businesses, staying informed about these trends can provide a competitive edge. So, is aluminum the ultimate choice? Perhaps, but continuous improvement is essential.

В заключение, алюминиевые крышки offer a compelling combination of lightness, strength, and sustainability that makes them an excellent choice for modern packaging. They reduce logistics costs through their low weight, protect products effectively with their durable and barrier properties, and support environmental goals via high recyclability. While alternatives exist, aluminum often provides a balanced solution that meets diverse needs across industries. By understanding the production process, applications, and future trends, businesses can make informed decisions that enhance product quality and brand reputation. So, next time you evaluate packaging options, ask yourself: could aluminum caps be the key to unlocking efficiency and appeal for your product? The answer might just be a resounding yes. Embrace innovation and choose wisely – your product deserves the best.

This article has explored the myriad aspects of aluminum caps, from their fundamental properties to practical considerations. We hope it has answered your questions and inspired you to consider aluminum for your packaging needs. Remember, in a world where details matter, the right cap can make all the difference.