В современном промышленном мире качество и надежность деталей литья играют ключевую роль в успехе любого предприятия. От автомобильной промышленности до аэрокосмической отрасли, от машиностроения до энергетики — превосходные отлитые детали являются основой инноваций и эффективности. В этой статье мы погрузимся в мир литья, раскроем его секреты и покажем, как вы можете достичь непревзойденного качества уже сегодня. Готовы ли вы к трансформации вашего производства? Давайте начнем!

Литье — это древнее искусство, которое эволюционировало в высокотехнологичный процесс, способный производить детали с точностью до микрона. С самого начала человеческой цивилизации литье использовалось для создания инструментов, оружия и украшений. Сегодня, с развитием технологий, оно стало незаменимым в промышленности. Представьте себе: без литья не было бы двигателей внутреннего сгорания, турбин, или даже простых бытовых приборов. Это процесс, который превращает сырье в функциональные шедевры инженерии.

Но почему именно литье? Ответ прост: оно предлагает уникальное сочетание экономической эффективности, scalability и способности создавать complex geometries. В отличие от других методов производства, таких как machining или additive manufacturing, литье позволяет mass-produce детали с минимальными отходами и высоким consistency. Это делает его идеальным для large-scale industrial applications.

Однако, не все литье создано equal. Качество варьируется в зависимости от материалов, технологий и expertise производителя. Вот где в игру входит превосходство. В этой статье мы explorate, как достичь этого превосходства, focusing на key аспектах: material selection, process optimization, and innovation.

Литье имеет богатую history, dating back to ancient times. The Bronze Age saw the first widespread use of casting for tools and artifacts. Fast forward to the Industrial Revolution, and casting became a cornerstone of mass production. Innovations like sand casting, investment casting, and die casting emerged, each offering unique advantages.

In the 20th century, advancements in metallurgy and engineering led to the development of precision casting techniques. Today, we are in the digital age, where computer-aided design (CAD) and simulation software have revolutionized the casting process. Technologies like 3D printing for molds and real-time monitoring ensure higher accuracy and reduced defects.

This evolution highlights the importance of embracing modern methods to achieve excellence. By understanding the past, we can better appreciate the advancements that make superior casting possible today.

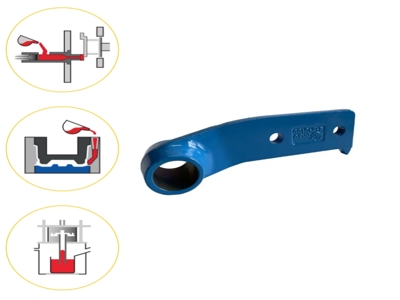

To excel in casting, one must master various technologies. Let's delve into the most impactful ones:

Incorporating digital tools like CFD simulation and AI-powered quality control can further enhance these processes, reducing defects and improving efficiency.

The choice of material is critical to casting excellence. Common materials include:

Material testing and certification, like ASTM standards, are essential to guarantee quality. Partnering with reputable suppliers ensures consistent material properties.

Achieving excellence in casting involves optimizing every step of the process:

Implementing Lean manufacturing principles and Six Sigma can streamline operations, reducing waste and improving yield.

The casting industry is continuously evolving with innovations such as:

Embracing these innovations not only improves quality but also positions companies as leaders in the market. The future of casting is digital, sustainable, and ultra-precise.

Investing in superior casting offers numerous benefits:

Case studies from industries like automotive show that companies adopting excellence in casting see a significant return on investment within months.

Ready to transform your casting operations? Follow these steps:

Start small with pilot projects to demonstrate value before scaling up. Remember, excellence is a journey, not a destination.

Мир промышленного литья full of opportunities for those who seek excellence. By leveraging advanced technologies, optimizing processes, and embracing innovation, you can produce parts that not only meet but exceed expectations. The journey to superiority may require investment and effort, but the rewards—in terms of cost savings, performance, and market leadership—are immense.

Don't wait for tomorrow. Start exploring the world of casting excellence today. Evaluate your current practices, seek out new technologies, and commit to continuous improvement. Your industrial parts deserve the best, and with the right approach, you can achieve just that.

Thank you for reading. If you have questions or need assistance, feel free to reach out to experts in the field. Together, we can shape the future of manufacturing.