В современном мире автомобильная промышленность стоит на пороге кардинальных изменений. С ростом экологических проблем, ужесточением норм выбросов и стремлением к повышению эффективности, производители ищут инновационные решения. Одним из таких прорывов являются революционные алюминиевые детали для машин. Эти компоненты не просто улучшают производительность транспортных средств, но и способны полностью перевернуть всю отрасль, предлагая беспрецедентные преимущества в весе, прочности, долговечности и экологичности.

Алюминий — это легкий, прочный и коррозионно-стойкий металл, который уже давно используется в различных отраслях, от аэрокосмической до строительной. Однако в автомобилестроении его потенциал только начинает раскрываться в полной мере. Традиционно автомобили изготавливались из стали, которая тяжелее и менее эффективна с точки зрения топливной экономичности. С внедрением алюминиевых деталей, инженеры смогли значительно снизить вес транспортных средств, что прямо влияет на уменьшение расхода топлива и выбросов CO2. Например, замена стальных компонентов на алюминиевые может снизить общий вес автомобиля на 10-15%, что эквивалентно экономии топлива до 7%.

Но почему именно сейчас алюминиевые детали становятся революционными? Ответ кроется в совпадении нескольких факторов: advancements в технологиях обработки металлов, растущее давление со стороны регуляторов на снижение выбросов, и increasing consumer demand for more efficient and environmentally friendly vehicles. Кроме того, алюминий легко поддается рециклингу, что делает его идеальным выбором для circular economy. В этой статье мы глубоко погрузимся в то, как эти детали меняют game, обсуждая ключевые преимущества, технологические инновации, case studies, и будущие тенденции.

Одним из самых значительных преимуществ алюминиевых деталей является их легкость. Алюминий имеет плотность примерно в три раза меньшую, чем сталь, что позволяет создавать более легкие конструкции без ущерба для прочности. Это прямо translates to improved fuel efficiency. For instance, studies show that every 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy. В эпоху, когда цены на топливо растут, а экологические нормы ужесточаются, это становится критически важным. Легковые автомобили, такие как Tesla Model S, extensively use aluminum in their body and chassis, contributing to their high efficiency and performance.

Кроме того, снижение веса улучшает handling and acceleration, making vehicles more responsive and enjoyable to drive. This is particularly important for electric vehicles (EVs), where battery weight is a major concern. By using aluminum parts, manufacturers can offset the weight of batteries, extending range and enhancing overall performance. For example, the Audi e-tron features an aluminum-intensive structure that helps achieve a range of over 400 kilometers on a single charge.

Несмотря на легкость, алюминиевые детали обладают выдающейся прочностью. Современные сплавы, такие как 6000 и 7000 series, offer tensile strengths comparable to some steels, while being much lighter. This makes them ideal for critical components like frames, bumpers, and engine parts. Алюминий также обладает excellent fatigue resistance, meaning it can withstand repeated stress without failing, which is crucial for automotive applications where vehicles are subjected to constant vibrations and impacts.

Долговечность алюминия further enhanced by its natural corrosion resistance. Unlike steel, which requires coatings or galvanization to prevent rust, aluminum forms a protective oxide layer that shields it from environmental factors. This reduces maintenance costs and extends the lifespan of vehicles. In harsh climates or for off-road vehicles, this property is invaluable. Case in point: many military and commercial trucks use aluminum components to ensure reliability in demanding conditions.

В контексте глобального движения towards sustainability, алюминиевые детали offer a green alternative. Алюминий is highly recyclable; in fact, over 75% of all aluminum ever produced is still in use today. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from bauxite ore, significantly reducing carbon footprint. This aligns with the automotive industry's goals to reduce environmental impact and adhere to regulations like the EU's Green Deal, which aims for carbon neutrality by 2050.

Moreover, the production process for aluminum parts is becoming more efficient. Advanced manufacturing techniques, such as additive manufacturing (3D printing) and precision casting, minimize waste and energy consumption. Companies like BMW and Toyota are investing in closed-loop recycling systems where aluminum scrap from production is reused, creating a circular economy model. This not only benefits the environment but also reduces costs for manufacturers, making it a win-win scenario.

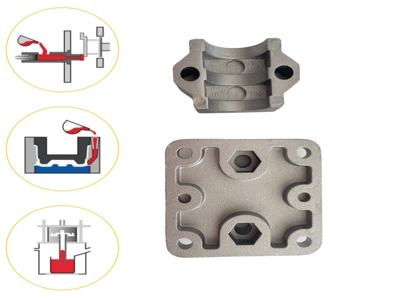

Производство алюминиевых деталей evolved significantly with innovations in machining and forming. Computer Numerical Control (CNC) machining allows for high-precision components with complex geometries, essential for modern vehicles where every gram counts. Additionally, hydroforming and hot stamping techniques enable the creation of strong, lightweight parts with reduced material waste. For instance, hydroforming uses fluid pressure to shape aluminum sheets into desired forms, resulting in components that are both light and durable.

Another breakthrough is the use of additive manufacturing. 3D printing with aluminum alloys allows for rapid prototyping and custom parts that were previously impossible to make with traditional methods. This accelerates development cycles and enables personalized solutions for specific vehicle models. Companies like Local Motors are pioneering 3D-printed aluminum parts for their vehicles, showcasing the potential for mass customization in the industry.

The rise of electric and autonomous vehicles has created new opportunities for aluminum parts. EVs benefit immensely from weight reduction, as it directly impacts battery efficiency and range. Aluminum is used in battery enclosures, motor housings, and structural components to keep weight down while maintaining safety standards. For example, the Nissan Leaf uses aluminum in its body to enhance efficiency, contributing to its popularity as an affordable EV.

In autonomous vehicles, weight and reliability are paramount. Aluminum parts contribute to the overall lightweight design, which is crucial for sensors and computing systems that require stable power sources. Additionally, the corrosion resistance of aluminum ensures that these high-tech components remain functional over time, even in varying weather conditions. As autonomy becomes more prevalent, the demand for advanced aluminum solutions will only grow.

Tesla Motors has been at the forefront of incorporating aluminum into their vehicles. The Tesla Model S, for instance, features an all-aluminum body, which reduces weight by approximately 200 kg compared to a steel equivalent. This has enabled the car to achieve impressive acceleration and range, setting new standards in the EV market. Tesla's use of aluminum extends to battery packs and drivetrains, showcasing how comprehensive integration can lead to revolutionary performance.

The company's Gigafactories utilize advanced aluminum processing techniques to scale production efficiently. By prioritizing lightweight materials, Tesla not only meets environmental goals but also enhances customer satisfaction through better driving experiences. This case study demonstrates that investing in aluminum technology can yield significant competitive advantages.

German automakers like Audi and BMW have long embraced aluminum for their high-end models. The Audi A8, for example, uses an aluminum space frame that provides exceptional rigidity and safety while keeping weight low. This innovation has trickled down to other models, such as the A6 and Q7, making aluminum a staple in their lineup. Similarly, BMW's i3 and i8 models incorporate aluminum and carbon fiber composites to achieve lightweighting goals.

These companies invest heavily in research and development to improve aluminum alloys and manufacturing processes. For instance, BMW's use of recycled aluminum in their production lines reduces environmental impact and costs. Such initiatives not only boost brand image but also drive industry-wide adoption of sustainable practices.

Looking ahead, the role of aluminum in the automotive industry is set to expand. With advancements in material science, we can expect even lighter and stronger alloys to emerge. Nanotechnology and composite materials may further enhance the properties of aluminum, making it suitable for more applications. Additionally, as autonomous and connected vehicles become mainstream, the need for durable, lightweight components will intensify.

The market for aluminum parts is projected to grow at a CAGR of 5-7% over the next decade, driven by increased adoption in EVs and emerging markets. Governments worldwide are incentivizing lightweight materials through subsidies and regulations, such as fuel economy standards in the US and China's NEV policies. This creates a fertile ground for innovation and investment.

However, challenges remain, such as the higher initial cost of aluminum compared to steel and the need for specialized manufacturing equipment. But as economies of scale improve and technologies advance, these barriers will diminish. Collaboration between automakers, suppliers, and research institutions will be key to unlocking the full potential of aluminum.

В заключение, революционные алюминиевые детали для машин — это не просто trend, а fundamental shift that is reshaping the automotive industry. От снижения веса и улучшения эффективности до экологичности и инноваций, алюминий offers a multitude of benefits that address current and future challenges. As manufacturers continue to adopt these technologies, we can expect to see vehicles that are lighter, safer, and more sustainable.

Для игроков отрасли, embracing aluminum parts is no longer an option but a necessity to stay competitive. Whether you are a producer, supplier, or consumer, understanding and investing in these advancements will pay dividends in the long run. The revolution is here, and it is aluminum-powered. Присоединяйтесь к движению и будьте частью change that will define the future of transportation.

Ключевые выводы:

Эта статья лишь scratches the surface of how aluminum parts are transforming the industry. For more insights, stay tuned to our updates and consider consulting with experts to integrate these solutions into your operations. The future is lightweight, and it is bright with aluminum.