В современном промышленном ландшафте, где конкуренция обостряется, а требования к эффективности и инновациям растут с каждым днем, кастомизированные промышленные компоненты становятся не просто опцией, а необходимостью. Эти специализированные детали, созданные под конкретные нужды производства, предлагают уникальные преимущества, которые стандартные компоненты не могут обеспечить. В этой статье мы глубоко погрузимся в мир кастомизированных промышленных компонентов, исследуя их значение, преимущества, процесс разработки, применение в различных отраслях, а также будущие тренды. Мы также обсудим, как выбрать правильного партнера для кастомизации и интегрировать эти решения в ваше производство для максимальной отдачи.

Промышленное производство эволюционировало от массового выпуска стандартизированных продуктов к более гибким и адаптивным моделям. Это изменение вызвано растущим спросом на персонализированные продукты, необходимостью оптимизации цепочек поставок и стремлением к устойчивому развитию. Кастомизированные компоненты играют ключевую роль в этом переходе, позволяя компаниям создавать оборудование и системы, которые точно соответствуют их операционным требованиям. Например, в автомобильной промышленности кастомизированные детали двигателя могут улучшить топливную эффективность, в то время как в фармацевтике специализированные компоненты для чистых помещений обеспечивают соблюдение строгих стандартов качества.

Исторически промышленность полагалась на стандартные компоненты из-за их доступности и низкой стоимости. Однако с развитием технологий, таких как 3D-печать и компьютерное проектирование (CAD), кастомизация стала более доступной и экономически эффективной. Это открыло новые возможности для инноваций, позволяя производителям экспериментировать с дизайном и материалами без значительных первоначальных инвестиций. Более того, в эпоху Industry 4.0, где данные и IoT (Интернет вещей) интегрируются в производственные процессы, кастомизированные компоненты могут быть оснащены датчиками для мониторинга в реальном времени, further enhancing their value.

В этой статье мы рассмотрим, как кастомизированные промышленные компоненты могут трансформировать ваше производство, начиная с понимания их основ и заканчивая практическими советами по внедрению. Мы также приведем примеры из реального мира и статистику, чтобы подкрепить наши аргументы. Цель — предоставить comprehensive руководство для руководителей производства, инженеров и decision-makers, которые стремятся leverage кастомизацию для competitive advantage.

Одним из наиболее значительных преимуществ кастомизированных компонентов является их способность повышать эффективность производства. Созданные specifically для вашего оборудования, они минимизируют трение, износ и downtime, что leads to higher productivity. Например, кастомизированный подшипник в конвейерной системе может reduce energy consumption на 15-20%, согласно исследованиям. Кроме того, эти компоненты often имеют longer lifespan, reducing the need for frequent replacements and lowering maintenance costs.

Another key benefit is cost savings in the long run. While initial costs for customization might be higher than off-the-shelf parts, the overall total cost of ownership (TCO) is often lower due to reduced waste, improved efficiency, and fewer failures. A study by Deloitte showed that companies using customized components reported up to 30% reduction in operational costs over five years. Additionally, customization allows for better inventory management, as you order only what you need, avoiding overstocking of standard parts that may not be fully utilized.

Flexibility and adaptability are also crucial. In a volatile market, the ability to quickly adjust production lines with customized components can be a game-changer. For instance, during the COVID-19 pandemic, many manufacturers shifted to producing medical equipment by customizing existing machinery, demonstrating how agility can drive resilience. Moreover, customized components enable innovation by allowing integration of new technologies, such as smart sensors for predictive maintenance, which can prevent costly breakdowns.

From an environmental perspective, customization supports sustainability. By designing components that fit perfectly, manufacturers can reduce material waste and energy consumption. For example, additive manufacturing (3D printing) for customized parts often uses less material than traditional subtractive methods. This aligns with global trends towards circular economy and green manufacturing, making it not only economically beneficial but also socially responsible.

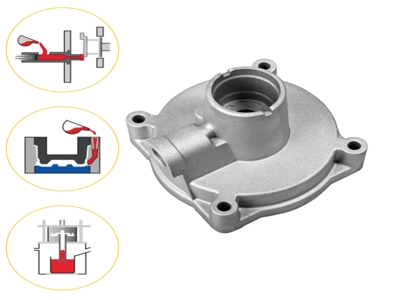

Разработка кастомизированных промышленных компонентов involves a collaborative process between the manufacturer and the supplier. It typically starts with a needs assessment, where the production requirements are analyzed in detail. This includes factors like load capacity, environmental conditions (e.g., temperature, corrosion), and compatibility with existing systems. Advanced tools like finite element analysis (FEA) and computational fluid dynamics (CFD) are used to simulate performance and ensure reliability.

Next, the design phase utilizes CAD software to create precise models. This stage allows for iterative testing and optimization without physical prototypes, saving time and resources. Once the design is finalized, prototyping begins, often using rapid prototyping techniques such as 3D printing to validate the concept. Feedback from testing is incorporated, and the design is refined until it meets all specifications.

Production follows, with methods tailored to the component's material and complexity. For metal parts, processes like CNC machining or casting might be used, while polymers could involve injection molding. Quality control is integral throughout, with inspections and certifications (e.g., ISO standards) ensuring that the components perform as intended. Post-production, support services such as installation guidance and maintenance plans are provided to ensure seamless integration.

This process requires close communication and expertise. Choosing a partner with experience in your industry is crucial, as they can offer insights and best practices. The entire cycle, from concept to delivery, can take weeks to months, depending on complexity, but the investment pays off in enhanced performance and longevity.

Кастомизированные компоненты find applications across diverse industries. In automotive, they are used for engine parts, transmission systems, and chassis components to improve fuel efficiency and safety. For example, customized pistons can enhance combustion efficiency, reducing emissions. In aerospace, where precision is critical, components like turbine blades are often customized to withstand extreme conditions, contributing to lighter and more efficient aircraft.

In the energy sector, customized parts are essential for renewable energy systems. Wind turbine gears or solar panel mounts designed specifically for local conditions can increase energy output and durability. Similarly, in oil and gas, corrosion-resistant components customized for harsh environments extend equipment life and reduce downtime.

The healthcare industry benefits greatly from customization, particularly in medical devices and equipment. Implants, surgical tools, and diagnostic machines are often tailored to patient-specific anatomy or hospital workflows, improving outcomes and efficiency. During the pandemic, rapid customization of ventilators and PPE demonstrated how vital this adaptability is.

Consumer goods and electronics also leverage customization for product differentiation. For instance, customized casings for smartphones or specialized components in home appliances can enhance user experience and brand loyalty. Overall, the ability to tailor components to specific needs drives innovation and competitiveness in every sector.

The future of customized industrial components is shaped by emerging technologies. Artificial intelligence (AI) and machine learning are revolutionizing design processes by predicting optimal configurations based on historical data. Digital twins—virtual replicas of physical systems—allow for real-time monitoring and customization adjustments without physical intervention.

Additive manufacturing, or 3D printing, is becoming more prevalent, enabling complex geometries and on-demand production that reduce lead times and waste. Materials science is also advancing, with new alloys and composites offering better performance characteristics for customized applications.

Sustainability will continue to be a driver, with a focus on recyclable and bio-based materials. The integration of IoT sensors into customized components will enable smarter, connected factories where data-driven decisions optimize production continuously. As global supply chains become more resilient, localized customization hubs may emerge, reducing dependency on distant suppliers.

These trends indicate a move towards hyper-personalization, where every component is uniquely designed for its specific role, further blurring the line between manufacturing and innovation.

Selecting the right partner for customized components is critical to success. Look for suppliers with a proven track record in your industry, as they will understand your specific challenges and regulations. Evaluate their technological capabilities, such as access to advanced CAD software, prototyping tools, and quality control systems.

Communication and collaboration are key; choose a partner who values transparency and provides regular updates throughout the process. Consider their scalability—can they handle large orders or rapid changes if needed? Cost is important, but focus on value rather than just price; a slightly higher initial cost might lead to significant long-term savings.

Request case studies or references from previous clients to gauge their reliability and performance. Ensure they comply with relevant standards (e.g., ISO 9001 for quality management) and offer post-sales support. A good partner will act as an extension of your team, contributing ideas and solutions to optimize your production.

Integrating customized components into your production line requires careful planning. Start with a pilot project to test the components in a controlled environment, measuring performance metrics like efficiency, downtime, and cost savings. Train your staff on the new parts to ensure proper installation and maintenance.

Update your inventory and maintenance schedules to accommodate the customized items. Use data from IoT-enabled components to monitor performance and schedule predictive maintenance, reducing unexpected failures. Gradually scale up integration based on successful results, and continuously gather feedback for further improvements.

This approach minimizes disruption and maximizes the benefits of customization, leading to a more resilient and efficient production system.

В заключение, кастомизированные промышленные компоненты предлагают transformative potential для modern production. От повышения эффективности и снижения затрат до поддержки инноваций и устойчивости, они являются ключевым элементом в staying competitive. By understanding the process, applications, and future trends, and by choosing the right partners, you can successfully integrate customization into your operations. Embrace this opportunity to create a production environment that is not only efficient but also adaptable to the ever-changing demands of the global market. Start small, think big, and watch your production thrive with customized solutions.