Алюминий, как один из наиболее распространенных металлов в мире, играет ключевую роль в различных отраслях промышленности, от аэрокосмической до строительной и автомобильной. Его легкость, коррозионная стойкость и отличная проводимость делают его незаменимым материалом. Однако эффективность производства алюминиевых изделий во многом зависит от выбранных технологий обработки. В этой статье мы подробно исследуем наиболее эффективные методы обработки алюминия, их преимущества, недостатки и современные инновации, которые помогают оптимизировать производственные процессы.

Обработка алюминия включает в себя широкий спектр технологий, направленных на преобразование сырого алюминия или его сплавов в готовые изделия. Эти технологии можно разделить на несколько категорий: механическая обработка, литье, прокатка, экструзия, сварка и поверхностная обработка. Каждая из них имеет свои особенности и применяется в зависимости от требований к конечному продукту. Эффективность этих методов определяется такими факторами, как скорость производства, качество поверхности, точность размеров, энергопотребление и экологическая безопасность.

С развитием технологий, традиционные методы постоянно совершенствуются, а новые подходы, такие как аддитивное производство (3D-печать) и использование искусственного интеллекта для оптимизации процессов, становятся все более распространенными. В этой статье мы рассмотрим каждую технологию в деталях, чтобы помочь производителям выбрать наиболее подходящие методы для своих нужд.

Механическая обработка является одним из самых распространенных методов работы с алюминием. Она включает в себя процессы, такие как токарная обработка, фрезерование, сверление и шлифование, которые используются для придания заготовке desired формы и размеров. Алюминий, благодаря своей мягкости и пластичности, относительно легко поддается механической обработке, но требует careful подбора инструментов и параметров для избежания дефектов, таких как заусенцы или перегрев.

Эффективность механической обработки зависит от использования современных станков с ЧПУ (числовым программным управлением), которые обеспечивают высокую точность и повторяемость. Например, высокоскоростное фрезерование позволяет significantly увеличить производительность while maintaining quality. Additionally, the use of coolant systems helps to reduce heat generation and tool wear, further enhancing efficiency.

In terms of innovation, advancements in tool materials, such as diamond-coated cutters, have improved the lifespan and performance of tools when working with aluminum. Moreover, simulation software can predict potential issues before actual machining, reducing waste and downtime. Overall, mechanical processing remains a highly effective method for producing complex parts with tight tolerances, making it indispensable in industries like aerospace and automotive.

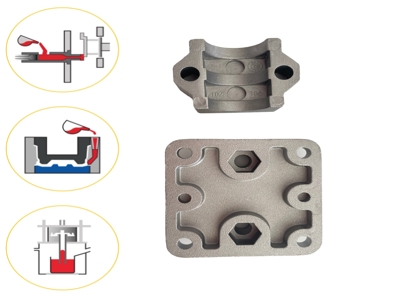

Литье – это процесс, при котором расплавленный алюминий заливается в форму для создания деталей desired shape. This method is particularly effective for mass production of components with intricate geometries. There are several types of casting, including sand casting, die casting, and investment casting, each with its own advantages.

Die casting, for instance, is highly efficient for high-volume production due to its fast cycle times and ability to produce parts with excellent surface finish. It is commonly used in the automotive industry for components like engine blocks and transmission cases. Sand casting, on the other hand, is more suitable for larger parts and lower volumes, offering flexibility at a lower cost.

To enhance efficiency, modern foundries employ automated systems for mold preparation and pouring, reducing human error and increasing throughput. Additionally, the use of computer simulations for mold design helps optimize the process, minimizing defects like porosity or shrinkage. Innovations such as vacuum-assisted casting improve the quality by reducing air entrapment, leading to stronger and more reliable parts. Casting is thus a cornerstone of aluminum processing, balancing cost-effectiveness with the ability to produce complex shapes.

Прокатка involves passing aluminum through rollers to reduce its thickness and achieve desired dimensions, typically used for producing sheets, plates, and foils. This process is crucial for industries that require flat aluminum products, such as packaging, construction, and electronics. The efficiency of rolling is measured by its ability to produce uniform thickness with high surface quality at high speeds.

Hot rolling is performed at elevated temperatures to make the aluminum more malleable, allowing for significant reduction in thickness. It is followed by cold rolling, which refines the surface finish and improves mechanical properties. Modern rolling mills are equipped with advanced control systems that monitor parameters like temperature and pressure in real-time, ensuring consistency and reducing material waste.

Innovations in rolling technology include the development of tandem mills, where multiple stands work sequentially to increase productivity. Additionally, the integration of IoT (Internet of Things) devices allows for predictive maintenance, minimizing downtime. Rolling is highly efficient for large-scale production, with minimal material loss, making it a preferred method for manufacturing aluminum sheets used in cans, automotive panels, and building materials.

Экструзия is a process where aluminum is forced through a die to create long products with constant cross-sections, such as rods, tubes, and profiles. This method is extremely efficient for producing complex shapes that are difficult to achieve with other techniques. It is widely used in construction for window frames, in transportation for railings, and in electronics for heat sinks.

The process begins with heating aluminum billets to a plastic state, then pressing them through a die using a hydraulic or mechanical press. The efficiency of extrusion depends on factors like die design, billet temperature, and press speed. Modern extruders utilize computer-aided design (CAD) for dies, enabling the production of intricate profiles with high precision.

To improve efficiency, direct extrusion methods reduce energy consumption by minimizing friction. Innovations such as quick-change die systems allow for faster transitions between different profiles, increasing overall productivity. Furthermore, the use of recycled aluminum in extrusion not only lowers costs but also supports sustainability efforts. Extrusion is highly effective for custom-shaped products, offering versatility and cost savings in medium to high-volume production.

Сварка is essential for joining aluminum components in assemblies, common in industries like shipbuilding, automotive, and aerospace. However, welding aluminum presents challenges due to its high thermal conductivity and tendency to form oxides, which can lead to defects if not properly managed. Effective welding techniques are crucial for ensuring strong, durable joints.

Common methods include TIG (tungsten inert gas) welding and MIG (metal inert gas) welding, which use inert gases to protect the weld pool from oxidation. TIG welding offers high precision and is suitable for thin materials, while MIG welding is faster and better for thicker sections. Laser welding and friction stir welding are more advanced techniques that provide higher efficiency and better quality with less distortion.

Efficiency in welding is enhanced by automated robotic systems that ensure consistency and reduce labor costs. Real-time monitoring systems detect defects early, preventing rework. Innovations like hybrid welding combine multiple energy sources to improve speed and penetration. Proper training and the use of filler materials compatible with aluminum alloys also contribute to effective welding, making it a vital technology for complex assemblies.

Поверхностная обработка includes processes like anodizing, painting, and powder coating, which enhance the appearance, corrosion resistance, and durability of aluminum products. Anodizing, for example, creates a protective oxide layer on the surface, making it harder and more resistant to wear. This is particularly important for architectural applications and consumer goods.

Efficiency in surface treatment is achieved through automated lines that handle cleaning, etching, and coating stages with minimal human intervention. Environmental considerations have led to the development of eco-friendly processes, such as chrome-free anodizing, which reduce harmful emissions. Additionally, advances in coating technologies, like nanotechnology-based coatings, offer superior protection with thinner layers, saving material and energy.

Innovations include digital printing on aluminum surfaces for custom designs, expanding its use in decorative applications. Overall, surface treatment not only improves product performance but also adds value, making it an integral part of aluminum processing for markets demanding high aesthetics and longevity.

The future of aluminum processing lies in the integration of digital technologies and sustainable practices. Additive manufacturing, or 3D printing, is gaining traction for prototyping and producing complex parts with reduced waste. Using aluminum powders, selective laser sintering can create lightweight components with intricate internal structures, ideal for aerospace and medical industries.

Artificial intelligence and machine learning are being applied to optimize process parameters, predict maintenance needs, and improve quality control. For instance, AI algorithms can analyze data from sensors in real-time to adjust extrusion speeds or welding temperatures, maximizing efficiency. The adoption of Industry 4.0 principles, such as interconnected smart factories, enables seamless communication between different processing stages, reducing lead times and costs.

Sustainability is another key focus, with efforts to increase the use of recycled aluminum, which requires only 5% of the energy needed for primary production. Water recycling systems in processing plants and the development of low-emission technologies contribute to a greener industry. As demand for lightweight and eco-friendly materials grows, these innovations will drive the evolution of aluminum processing, ensuring it remains efficient and competitive.

В заключение, эффективность обработки алюминия в производстве зависит от выбора appropriate технологий, адаптированных к specific applications. Механическая обработка, литье, прокатка, экструзия, сварка и поверхностная обработка – все эти методы offer unique advantages and can be highly efficient when implemented with modern equipment and innovations. The integration of digital tools, automation, and sustainable practices further enhances productivity and quality.

Producers should consider factors such as production volume, part complexity, and cost when selecting processing methods. By staying abreast of technological advancements, the aluminum industry can continue to meet the demands of various sectors while minimizing environmental impact. Ultimately, the most effective technology is one that balances efficiency, quality, and sustainability, ensuring long-term success in the competitive market.

This article has provided a comprehensive overview of the key technologies, but continuous learning and adaptation are essential for leveraging the full potential of aluminum processing.