В современной конкурентной бизнес-среде компании постоянно ищут способы оптимизации своих операций, снижения затрат и улучшения качества продукции. Одним из ключевых инструментов для достижения этих целей является использование услуг ODM (Original Design Manufacturing) для алюминиевых деталей. ODM предлагает уникальные возможности для бизнеса, позволяя сосредоточиться на основных компетенциях, в то время как эксперты занимаются проектированием и производством компонентов. В этой статье мы подробно рассмотрим преимущества ODM алюминиевых деталей, подкрепляя аргументы примерами и статистикой, чтобы показать, как это может трансформировать ваш бизнес.

Одним из наиболее значительных преимуществ ODM является возможность существенной экономии затрат. При традиционном подходе компании должны инвестировать в собственное производственное оборудование, нанимать персонал и управлять цепочками поставок, что требует значительных капиталовложений и операционных расходов. ODM позволяет избежать этих затрат, передавая производство специализированным партнерам. Например, по данным исследования McKinsey, компании, использующие ODM, могут снизить общие затраты на производство на 20-30% благодаря масштабированию и оптимизации процессов. Алюминиевые детали, производимые через ODM, часто обходятся дешевле due to economies of scale, так как ODM-партнеры работают с multiple клиентами и могут распределять fixed costs.

Кроме того, ODM способствует повышению операционной эффективности. Партнеры ODM обладают экспертизой в проектировании и производстве, что позволяет сократить время вывода продукции на рынок. Это особенно важно в отраслях, где скорость инноваций критична, таких как automotive или aerospace. Сокращение lead time на 15-25% может дать бизнесу конкурентное преимущество, позволяя быстрее реагировать на рыночные изменения и запросы клиентов.

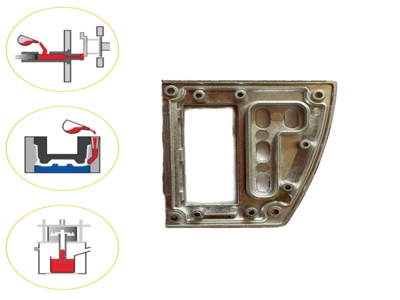

ODM предоставляет unparalleled возможности для кастомизации алюминиевых деталей. В отличие от off-the-shelf решений, ODM позволяет адаптировать дизайн, размеры и свойства компонентов под specific needs бизнеса. Это особенно beneficial в industries, где требования к продукции highly specialized, например, в медицинском оборудовании или consumer electronics. Партнеры ODM используют advanced CAD software и prototyping techniques to create tailor-made solutions that meet exact specifications.

Гибкость ODM также проявляется в ability to scale production up or down based on demand. Это reduces the risk of overproduction or stockouts, which can lead to financial losses. For instance, during the COVID-19 pandemic, many companies leveraged ODM to quickly pivot production to essential items, demonstrating the adaptability of this model. In the context of aluminum parts, this flexibility ensures that businesses can respond to market fluctuations without committing to long-term capital investments.

Качество продукции является критическим фактором для любого бизнеса, и ODM помогает обеспечить high standards through specialized expertise and rigorous quality control processes. ODM partners often have ISO certifications and implement strict testing protocols to ensure that aluminum parts meet industry standards and customer requirements. This reduces the likelihood of defects and recalls, which can damage brand reputation and incur costs.

Moreover, ODM allows for better control over the supply chain. By working closely with a single partner, businesses can monitor production stages and implement corrective actions in real-time. This collaborative approach fosters transparency and trust, leading to improved product quality. For example, in the automotive industry, where safety is paramount, ODM partnerships have been shown to enhance the reliability of components like engine parts or chassis elements made from aluminum.

ODM partners are often at the forefront of technological advancements, providing businesses access to cutting-edge innovations without the need for in-house R&D investments. This is particularly valuable for aluminum parts, where new alloys, manufacturing techniques (e.g., additive manufacturing or CNC machining), and sustainability practices are constantly evolving. By leveraging ODM, companies can incorporate these innovations into their products, staying ahead of competitors.

For instance, the adoption of lightweight aluminum alloys in aerospace has been driven by ODM collaborations, resulting in fuel-efficient aircraft. Similarly, in consumer electronics, ODM enables the production of sleek, durable aluminum casings that enhance product appeal. This access to technology not only improves product performance but also supports sustainability goals, as advanced manufacturing processes can reduce waste and energy consumption.

Outsourcing production through ODM allows businesses to concentrate on their core activities, such as marketing, sales, and customer service. This strategic focus can lead to increased innovation and growth in areas where the company has a competitive advantage. For example, a tech startup might use ODM for aluminum components of its devices while dedicating resources to software development and user experience.

This division of labor enhances overall business efficiency and agility. It reduces the managerial burden associated with production, enabling leaders to make faster decisions and adapt to market changes. In the long run, this can result in higher profitability and market share, as companies can allocate resources more effectively.

ODM helps mitigate various business risks, including supply chain disruptions, regulatory compliance issues, and technological obsolescence. Partners often have diversified supply networks and expertise in navigating global trade regulations, reducing vulnerability to events like geopolitical tensions or natural disasters. For aluminum parts, which may be subject to tariffs or environmental regulations, ODM providers can ensure compliance and smooth operations.

Additionally, ODM enhances business resilience by providing a buffer against demand volatility. During economic downturns, companies can scale back production without facing the fixed costs of maintaining in-house facilities. This flexibility was evident during the 2008 financial crisis, where businesses using ODM recovered more quickly than those with rigid production models.

Speed to market is a critical competitive advantage, and ODM significantly accelerates the product development cycle. With dedicated teams focused on design and manufacturing, businesses can reduce the time from concept to commercialization. This is especially important in fast-paced industries like consumer goods or technology, where first-mover advantage can determine success.

For aluminum parts, ODM enables rapid prototyping and iteration, allowing for quick validation of designs and feedback incorporation. This iterative process minimizes errors and ensures that the final product meets market expectations. Case studies show that companies using ODM can cut time-to-market by up to 40%, leading to increased revenue opportunities.

Sustainability is increasingly important for businesses and consumers alike. ODM can contribute to environmental goals by optimizing resource use and reducing waste. Aluminum is a highly recyclable material, and ODM partners often employ eco-friendly practices, such as using recycled aluminum or energy-efficient manufacturing processes. This not only reduces the carbon footprint but also aligns with corporate social responsibility initiatives.

Moreover, ODM promotes circular economy principles by designing products for longevity and recyclability. For example, in the construction industry, aluminum parts produced through ODM can be easily disassembled and reused, minimizing environmental impact. This focus on sustainability can enhance brand image and attract environmentally conscious customers.

ODM fosters strong, collaborative relationships between businesses and manufacturers. These partnerships are built on trust and mutual benefit, leading to long-term synergies. Over time, ODM partners gain deep insights into the business's needs, allowing for continuous improvement and innovation. This collaborative approach can result in co-developed products that better serve market demands.

For instance, in the automotive sector, long-term ODM partnerships have led to the development of custom aluminum components that improve vehicle performance and safety. Such collaborations often extend beyond production to include joint R&D efforts, further driving innovation and value creation.

ODM provides businesses with access to global markets and expertise. Many ODM partners operate internationally, offering insights into regional trends and regulations. This global perspective can help companies expand their reach and enter new markets more efficiently. For aluminum parts, which are used worldwide, ODM can facilitate compliance with local standards and customs, reducing barriers to entry.

Additionally, ODM enables businesses to leverage cost advantages in different regions, such as lower labor costs in certain countries, while maintaining quality control. This globalization of production can lead to significant competitive advantages and increased market penetration.

В заключение, использование услуг ODM для алюминиевых деталей предлагает многочисленные преимущества для бизнеса, включая экономию затрат, кастомизацию, повышение качества, доступ к инновациям, и многое другое. Эти преимущества не только enhance operational efficiency but also drive growth and competitiveness in an increasingly complex market environment. By partnering with ODM providers, businesses can focus on their core strengths while leveraging external expertise to produce high-quality, customized aluminum parts. As industries continue to evolve, ODM will play a pivotal role in shaping the future of manufacturing, making it an essential strategy for any forward-thinking company.

To fully capitalize on these benefits, businesses should carefully select ODM partners based on their expertise, track record, and alignment with company values. With the right collaboration, ODM can transform challenges into opportunities, paving the way for sustained success and innovation.

Эта статья предоставлена в информационных целях и основана на общих industry insights. Для конкретных рекомендаций consult with experts in the field.