В эпоху глобального экологического кризиса и растущих затрат на сырье, промышленные предприятия все чаще сталкиваются с необходимостью оптимизации производственных процессов. Одним из ключевых направлений такой оптимизации является использование алюминиевых отливок на заказ, которые не только обеспечивают высокую точность и качество изделий, но и способствуют значительной экономии ресурсов. Алюминий, как легкий и прочный металл, обладает уникальными свойствами, делающими его идеальным материалом для широкого спектра применений — от аэрокосмической отрасли до автомобилестроения и строительства. Однако массовое производство стандартизированных компонентов часто приводит к перерасходу материалов, энергопотреблению и образованию отходов. В этом контексте индивидуальное литье алюминия представляет собой стратегический подход, позволяющий минимизировать эти негативные воздействия. Данная статья углубленно анализирует, как заказные алюминиевые отливки способствуют экономии ресурсов, рассматривая технические, экономические и экологические аспекты. Мы изучим процессы литья, сравнительные преимущества перед другими методами производства, и представим практические примеры из различных отраслей. К концу чтения станет ясно, что инвестиции в кастомные отливки — это не просто технологический выбор, а crucial шаг towards устойчивому развитию и повышению конкурентоспособности предприятий.

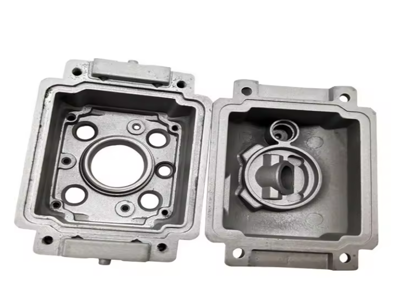

Алюминиевое литье — это процесс формования расплавленного алюминия в заданные формы для создания деталей с complex geometry. Основные методы включают литье под давлением, литье в песчаные формы, и литье по выплавляемым моделям. Каждый из этих методов может быть адаптирован для индивидуальных заказов, что позволяет оптимизировать использование материала. Например, при литье под давлением, точность процесса снижает необходимость в дополнительной механической обработке, тем самым экономя энергию и сокращая отходы. Исследования показывают, что customized литье может уменьшить материалоемкость на 15-20% по сравнению со стандартными методами, так как designers могут точно рассчитать объем metal, необходимый для каждой детали, избегая излишков. Кроме того, алюминий обладает высокой recyclability: до 95% metal может быть переплавлено и reused без потери качества, что further усиливает resource efficiency. В условиях, когда мировая добыча bauxite (основного сырья для алюминия) сопровождается significant environmental degradation, such as deforestation and water pollution, переход на efficient литье methods становится imperative. Таким образом, заказные отливки not only enhance product performance но и directly contribute to conservation of natural resources by minimizing raw material extraction and waste generation.

Экономия ресурсов через заказные алюминиевые отливки translates into tangible financial benefits for businesses. Во-первых, reduced material usage lowers direct costs on raw materials, which can account for up to 40% of production expenses in metalworking industries. Например, в automotive sector, где weight reduction is critical for fuel efficiency, customized castings allow for lightweight designs без compromizing strength, leading to savings on fuel and compliance with emissions regulations. Secondly, the precision of custom castings minimizes post-production machining, reducing labor costs and machine time. A case study from a German automotive supplier showed that switching to custom aluminum castings for engine components resulted in a 12% decrease in overall production costs due to less scrap and faster assembly. Additionally, the longevity and durability of aluminum parts mean fewer replacements over time, further conserving resources and reducing lifecycle costs. From a macroeconomic perspective, widespread adoption of such practices could lead to lower inflation in metal prices and enhanced supply chain resilience. However, initial investment in tooling and design for custom castings can be higher, but the long-term ROI often justifies it, especially when considering environmental taxes and incentives for sustainable practices. Thus, ordering custom aluminum castings is not just an ecological choice but a smart economic strategy that aligns with modern business models focused on efficiency and sustainability.

Заказные алюминиевые отливки играют pivotal role in mitigating environmental impact, primarily through resource conservation and emission reduction. The production of primary aluminum is energy-intensive, requiring approximately 14-16 kWh per kg, which contributes significantly to carbon emissions if powered by fossil fuels. By optimizing material use via custom castings, the demand for primary aluminum decreases, indirectly reducing energy consumption and associated greenhouse gas emissions. For instance, a study by the International Aluminum Institute indicates that every 1% reduction in material waste in casting processes can save up to 2.5 million tonnes of CO2 emissions annually globally. Furthermore, aluminum's recyclability means that custom castings often incorporate recycled content, which uses only 5% of the energy required for primary production. This circular economy approach not only conserves resources but also minimizes landfill waste. In practical terms, industries such as aerospace have adopted custom castings to create lighter aircraft components, leading to lower fuel consumption and emissions during operation. The environmental benefits extend beyond carbon: reduced mining activities preserve biodiversity and water resources. Regulatory frameworks like the EU's Circular Economy Action Plan are increasingly rewarding companies that adopt such practices with tax breaks and certifications, making custom castings a forward-looking investment. Therefore, ordering aluminum castings on demand is a proactive step towards achieving corporate sustainability goals and complying with global environmental standards.

Advances in technology are continuously enhancing the resource-saving potential of custom aluminum castings. additive manufacturing, or 3D printing, is revolutionizing the field by enabling the production of complex geometries with minimal material waste. Unlike traditional subtractive methods, 3D printing builds parts layer by layer, using only the necessary amount of aluminum, which can reduce material usage by up to 30%. digital twin technology allows for virtual testing and optimization of designs before physical production, further minimizing trial-and-error waste. In the near future, integration of AI and IoT in casting processes will enable real-time monitoring and adjustment, ensuring maximum efficiency. For example, smart foundries can use sensors to control melting temperatures and flow rates, reducing energy consumption by 10-15%. Additionally, developments in alloy science are creating lighter and stronger aluminum composites, which require less material for the same performance. These innovations not only save resources but also open new applications in sectors like renewable energy, where lightweight and durable components are essential. As global demand for sustainable solutions grows, the market for custom castings is expected to expand, driven by trends such as electric vehicles and green building. Embracing these technologies early can give companies a competitive edge while contributing to global resource conservation efforts.

To fully leverage the resource-saving benefits of custom aluminum castings, businesses should follow a structured approach. start by conducting a life cycle assessment (LCA) to identify areas where custom castings can reduce waste and energy use. Partner with experienced foundries that specialize in sustainable practices, such as using renewable energy for melting processes. invest in design software that optimizes part geometry for minimal material usage, like topology optimization tools. case studies illustrate success: in the construction industry, a company switched to custom aluminum beams for a skyscraper project, reducing material weight by 25% and cutting transportation emissions. In consumer electronics, custom castings for heat sinks improved thermal management while using 20% less aluminum. Another example is from the marine sector, where customized propeller castings enhanced efficiency and reduced fuel consumption by 15%. These real-world examples demonstrate that the initial costs are offset by long-term savings and environmental benefits. Additionally, educate stakeholders on the importance of resource conservation to foster a culture of sustainability. By implementing these strategies, companies can not only improve their bottom line but also contribute to a more sustainable future, making custom aluminum castings a wise choice for any forward-thinking organization.

В заключение, заказ алюминиевых отливок на заказ представляет собой мощный инструмент для экономии ресурсов, combining technical precision, economic savings, and environmental stewardship. Through reduced material waste, lower energy consumption, and enhanced recyclability, custom castings address critical challenges of modern industry. As we face escalating resource scarcity and climate change, adopting such practices is not optional but essential. Businesses are encouraged to explore partnerships with innovative foundries, invest in advanced technologies, and prioritize sustainability in their supply chains. By doing so, they can achieve competitive advantages while contributing to global conservation efforts. The future of manufacturing lies in efficiency and responsibility, and custom aluminum castings are at the forefront of this transformation. Let's embrace this opportunity to build a resource-efficient world together.