В современном инженерном мире надежность и долговечность компонентов являются ключевыми факторами успеха в различных отраслях, от автомобилестроения до промышленного оборудования. Среди множества материалов алюминий выделяется своими уникальными свойствами, делая его идеальным выбором для деталей передач. В этой статье мы глубоко погрузимся в тему прочных алюминиевых деталей передач, исследуя их преимущества, применения и будущие тенденции. Мы рассмотрим, как алюминиевые сплавы обеспечивают непревзойденную надежность, снижают вес систем и повышают общую эффективность, поддерживая устойчивое развитие и инновации.

Алюминий, как материал, известен своей легкостью, коррозионной стойкостью и отличной обрабатываемостью. Эти свойства делают его особенно привлекательным для использования в деталях передач, таких как шестерни, валы и корпуса, где вес и долговечность играют критическую роль. Передачи являются сердцем многих механических систем, преобразуя и передавая движение и мощность. Использование алюминия в этих компонентах не только улучшает производительность, но и способствует снижению энергопотребления и выбросов, что актуально в эпоху экологической осознанности.

Исторически, сталь и чугун доминировали в производстве деталей передач из-за их прочности и износостойкости. Однако с развитием технологий и увеличением требований к эффективности, алюминиевые сплавы начали завоевывать популярность. Современные алюминиевые сплавы, такие как серии 6000 и 7000, предлагают прочность, сопоставимую с некоторыми сталями, но при значительно меньшем весе. Это делает их незаменимыми в автомобильной промышленности, аэрокосмической отрасли и робототехнике, где каждый грамм на счету.

В этой статье мы подробно обсудим, как прочные алюминиевые детали передач обеспечивают надежность и долговечность. Мы рассмотрим ключевые аспекты, включая свойства материалов, процессы производства, тестирование и реальные применения. Кроме того, мы затронем экономические и экологические преимущества, а также будущие инновации в этой области. Цель – предоставить comprehensive обзор, который поможет инженерам, designers и decision-makers понять ценность алюминиевых деталей передач и внедрить их в свои проекты.

Алюминиевые сплавы обладают уникальным сочетанием свойств, которые делают их идеальными для деталей передач. Во-первых, низкая плотность алюминия (примерно 2.7 г/см³) значительно снижает вес компонентов по сравнению с сталью (плотность около 7.8 г/см³). Это приводит к уменьшению инерции в движущихся частях, что улучшает динамику систем и снижает энергопотребление. Например, в автомобильных трансмиссиях использование алюминиевых шестерен может снизить общий вес vehicle, повышая топливную экономичность и reducing выбросы CO2.

Коррозионная стойкость – еще одно важное преимущество. Алюминий естественным образом образует protective oxide layer на поверхности, который предотвращает ржавчину и degradation в harsh средах. Это особенно ценно в морских applications или промышленных settings, where влажность и chemicals могут повредить традиционные материалы. Добавление легирующих элементов, such as magnesium, silicon, и zinc, further enhances прочность и durability сплавов. For instance, сплав 6061 широко используется для его high strength-to-weight ratio и хорошей свариваемости.

Теплопроводность алюминия также играет ключевую роль в передачи. Высокая thermal conductivity помогает dissipate heat, generated during operation, reducing risk перегрева и износа. Это важно в high-speed передачах, where трение can lead to thermal expansion и failure. Кроме того, алюминиевые сплавы могут быть easily обработаны through литье, экструзия, или механическая обработка, allowing for complex geometries и precise tolerances. This flexibility in manufacturing enables production of customized деталей для specific applications, enhancing overall system performance.

Однако, алюминий имеет lower hardness и wear resistance compared to steel, which can be a limitation in high-load scenarios. To address this, surface treatments such as anodizing или coating with hard materials like diamond-like carbon (DLC) are applied to improve wear resistance. Additionally, heat treatment processes like solution treatment and aging can significantly increase the strength of aluminum alloys, making them suitable for demanding applications. For example, alloy 7075, after proper heat treatment, can achieve tensile strengths comparable to some steels, while maintaining light weight.

In summary, the properties of aluminum alloys—light weight, corrosion resistance, thermal conductivity, and machinability—make them excellent choices for transmission parts. By leveraging these attributes, engineers can design more efficient, reliable, and durable systems. The ongoing research into new alloy compositions and treatments continues to expand the possibilities, ensuring that aluminum remains a forefront material in transmission technology.

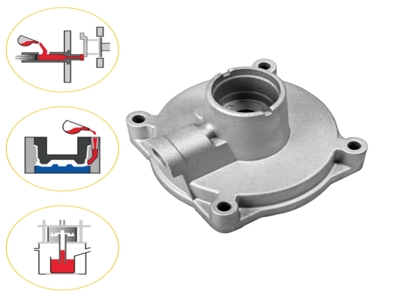

Производство прочных алюминиевых деталей передач involves various advanced processes that ensure high quality and precision. One of the most common methods is die casting, which is ideal for mass production of complex shapes. In die casting, molten aluminum is injected into a mold under high pressure, resulting in parts with excellent dimensional accuracy and surface finish. This process is widely used for automotive transmission housings and gears, where cost-effectiveness and speed are crucial. However, die casting can introduce porosity in the material, which may affect strength; therefore, subsequent processes like heat treatment or machining are often employed to enhance properties.

Another key process is extrusion, where aluminum billets are forced through a die to create long, continuous profiles with consistent cross-sections. Extrusion is particularly useful for producing shafts and rods used in transmissions. It allows for the creation of lightweight, strong components with minimal waste. After extrusion, parts can be further processed through cutting, drilling, or finishing operations to meet specific requirements. The flexibility of extrusion makes it suitable for custom applications in industries like aerospace and robotics.

Machining, including CNC (Computer Numerical Control) milling and turning, is essential for achieving high precision in aluminum transmission parts. CNC machines can produce gears with exact tooth profiles, ensuring smooth operation and minimal noise. Advanced software simulations help optimize the machining process, reducing material waste and improving efficiency. For instance, in the production of high-performance automotive gears, CNC machining is used to create helical or spur gears with tight tolerances, enhancing the overall reliability of the transmission system.

Additive manufacturing, or 3D printing, is an emerging technology that offers new possibilities for aluminum transmission parts. Techniques like selective laser melting (SLM) allow for the creation of complex, lightweight structures that are difficult to achieve with traditional methods. This is particularly beneficial for prototyping and custom parts, enabling rapid iteration and innovation. Although currently more expensive for mass production, additive manufacturing is gaining traction in high-value applications such as motorsports and defense, where weight reduction and performance are paramount.

Quality control is integral to the manufacturing process. Non-destructive testing methods, such as X-ray inspection and ultrasonic testing, are used to detect internal defects like cracks or voids. Additionally, mechanical testing, including tensile and hardness tests, ensures that the parts meet the required specifications. By combining these processes, manufacturers can produce aluminum transmission parts that are not only strong and durable but also cost-effective and environmentally friendly, thanks to aluminum's recyclability.

Автомобильная промышленность является одним из крупнейших потребителей алюминиевых деталей передач, благодаря постоянному стремлению к снижению веса и повышению эффективности. В современных автомобилях трансмиссионные системы, включая коробки передач, differentials, и driveshafts, increasingly incorporate aluminum components to reduce overall vehicle weight. This weight reduction directly translates to improved fuel economy and lower emissions, aligning with global regulations such as Euro 6 and CAFE standards. For example, many luxury and electric vehicles use aluminum transmission housings and gears to achieve better performance and range.

In automatic transmissions, aluminum is used for valve bodies, pump housings, and clutch plates due to its excellent thermal management properties. The high thermal conductivity of aluminum helps dissipate heat generated during operation, preventing overheating and ensuring smooth shifting. Additionally, the corrosion resistance of aluminum protects these components from degradation caused by transmission fluids and environmental factors, extending their lifespan and reducing maintenance costs. Brands like BMW and Audi have pioneered the use of aluminum in their transmission systems, showcasing its reliability in high-performance applications.

Electric vehicles (EVs) represent a growing market where aluminum transmission parts are particularly valuable. EVs require lightweight components to maximize battery efficiency and range. Aluminum gears and shafts in reduction gearboxes help minimize weight while maintaining strength, contributing to the overall efficiency of the electric drivetrain. Moreover, the quiet operation of aluminum parts reduces noise, vibration, and harshness (NVH), enhancing the driving experience. Companies like Tesla extensively use aluminum in their powertrains, demonstrating its suitability for innovative automotive technologies.

Beyond passenger cars, commercial vehicles and motorcycles also benefit from aluminum transmission parts. In trucks and buses, weight reduction leads to higher payload capacity and better fuel economy. Aluminum differential cases and gearboxes are common in these applications, offering durability under heavy loads. In motorcycles, aluminum transmission components contribute to agile handling and improved acceleration, making them popular in sport and racing models. The versatility of aluminum allows it to be tailored to various automotive segments, from everyday commuting to high-performance racing.

Looking ahead, the trend towards electrification and autonomous driving will further drive the adoption of aluminum in transmissions. As vehicles become more connected and efficient, the demand for lightweight, reliable materials will only increase. Research into new aluminum alloys and hybrid materials (e.g., aluminum composites) promises even greater performance gains. By embracing these innovations, the automotive industry can continue to reduce its environmental footprint while delivering superior driving experiences.

Помимо автомобильной промышленности, прочные алюминиевые детали передач находят широкое применение в различных отраслях, включая aerospace, robotics, marine, и heavy machinery. В аэрокосмической отрасли вес является критическим фактором, и алюминиевые сплавы используются в transmission systems самолетов и космических аппаратов для снижения массы без ущерба для прочности. Например, в landing gear mechanisms и actuator systems, aluminum gears и shafts обеспечивают reliable operation under extreme conditions, contributing to safety and efficiency.

In robotics and automation, precision and lightweight are essential for dynamic movement. Aluminum transmission parts, such as gears and belts, are used in robotic arms and CNC machines to achieve high accuracy and speed. The low inertia of aluminum components allows for faster acceleration and deceleration, improving productivity in manufacturing processes. Additionally, the corrosion resistance of aluminum makes it suitable for cleanroom environments or applications where hygiene is important, such as in food processing or pharmaceutical industries.

Marine applications benefit from aluminum's corrosion resistance in saltwater environments. Transmission components in boats and ships, such as propeller shafts and gearboxes, are often made from aluminum alloys to prevent rust and reduce maintenance. The lightweight nature of aluminum also helps improve fuel efficiency and maneuverability of vessels. In renewable energy, wind turbines use aluminum gears in their yaw and pitch systems to withstand harsh weather conditions and ensure reliable power generation.

Heavy machinery, such as construction equipment and agricultural machines, relies on durable transmission parts to handle high loads and abrasive conditions. Aluminum components, when properly treated, can offer a good balance of strength and weight, reducing operator fatigue and energy consumption. For instance, in excavators or tractors, aluminum transmission housings help distribute weight evenly, enhancing stability and performance. The recyclability of aluminum aligns with sustainability goals in these industries, promoting circular economy practices.

Emerging applications include medical devices and consumer electronics, where miniaturization and reliability are key. Aluminum transmission parts in surgical robots or precision instruments ensure smooth and accurate operations. In summary, the versatility of aluminum transmission parts across industries underscores their importance in modern engineering. As technology advances, we can expect to see even more innovative uses, driven by the need for efficiency, sustainability, and performance.

Надежность алюминиевых деталей передач обеспечивается through rigorous testing and quality assurance processes. Mechanical testing is fundamental, involving tensile tests to measure strength, hardness tests to assess wear resistance, and fatigue tests to evaluate durability under cyclic loading. For example, fatigue testing simulates the repeated stresses that transmission parts endure during operation, ensuring they can withstand long-term use without failure. Standards such as ISO and ASTM provide guidelines for these tests, helping manufacturers maintain consistency and reliability.

Non-destructive testing (NDT) methods play a crucial role in detecting internal flaws that could compromise performance. Techniques like ultrasonic testing use high-frequency sound waves to identify cracks or voids within the material, while X-ray imaging reveals hidden defects without damaging the part. These methods are especially important for safety-critical applications, such as in aerospace or automotive transmissions, where failure could have severe consequences. Regular inspections during manufacturing help catch issues early, reducing waste and ensuring high-quality output.

Environmental testing evaluates how aluminum parts perform under various conditions, such as extreme temperatures, humidity, or corrosive environments. For instance, salt spray tests assess corrosion resistance by exposing parts to a saline mist, simulating marine or winter road conditions. Thermal cycling tests check for dimensional stability and material integrity when subjected to temperature fluctuations. These tests ensure that aluminum transmission parts can operate reliably in real-world scenarios, from arctic cold to desert heat.

Field testing and real-world applications provide valuable feedback on reliability. Collaborations with OEMs (Original Equipment Manufacturers) allow for long-term monitoring of aluminum parts in actual use. Data collected from these trials help identify potential improvements and validate design choices. For example, in automotive transmissions, field data might show that aluminum gears have a longer lifespan than steel counterparts in certain conditions, leading to broader adoption. Continuous improvement based on testing results drives innovation and enhances trust in aluminum components.

In conclusion, the reliability of aluminum transmission parts is backed by comprehensive testing protocols that cover mechanical, environmental, and practical aspects. By adhering to these standards, manufacturers can deliver products that meet the highest levels of performance and safety. As materials science advances, new testing methods and simulations will further optimize reliability, ensuring that aluminum remains a top choice for transmission applications worldwide.

Использование алюминиевых деталей передач offers significant economic and environmental benefits. Economically, the lightweight nature of aluminum reduces material costs in terms of weight-based pricing and transportation. For manufacturers, lower weight means less energy required for machining and handling, leading to cost savings throughout the supply chain. Additionally, the machinability of aluminum allows for faster production times and reduced tool wear compared to harder materials like steel, further lowering manufacturing expenses. In the long run, the durability of aluminum parts reduces maintenance and replacement costs, providing a better return on investment for end-users.

From an environmental perspective, aluminum is highly recyclable, with over 75% of all aluminum ever produced still in use today. Recycling aluminum requires only 5% of the energy needed to produce primary aluminum from bauxite ore, significantly reducing greenhouse gas emissions. This circular economy approach minimizes waste and conserves natural resources. In transmission applications, the weight reduction achieved with aluminum contributes to lower fuel consumption in vehicles and machinery, directly cutting CO2 emissions. For example, studies show that a 10% reduction in vehicle weight can improve fuel efficiency by 6-8%, highlighting the environmental impact of lightweight materials.

The lifecycle assessment (LCA) of aluminum transmission parts often shows a lower environmental footprint compared to alternatives. LCA considers factors like raw material extraction, production, use, and end-of-life recycling. Aluminum scores well due to its recyclability and energy efficiency in use phases. Governments and organizations promote the use of aluminum through regulations and incentives aimed at sustainability, such as carbon credits or green manufacturing certifications. By choosing aluminum, companies can enhance their corporate social responsibility (CSR) profiles and meet consumer demands for eco-friendly products.

Innovations in aluminum production, such as using renewable energy in smelting processes, are further reducing the environmental impact. For instance, some manufacturers now operate smelters powered by hydropower or solar energy, making aluminum production nearly carbon-neutral. These advancements align with global goals like the Paris Agreement, supporting the transition to a low-carbon economy. In transmission systems, the combination of economic savings and environmental benefits makes aluminum an attractive choice for forward-thinking industries.

In summary, the economic and environmental advantages of aluminum transmission parts are clear: they offer cost savings, reduce emissions, and support sustainable practices. As awareness of climate change grows, the adoption of aluminum will likely increase, driven by both regulatory pressures and market preferences. By investing in aluminum technologies, businesses can not only improve their bottom line but also contribute to a healthier planet.

Будущее алюминиевых деталей передач bright, with ongoing innovations poised to enhance their performance and applicability. One key trend is the development of advanced aluminum alloys with improved properties. Researchers are experimenting with nano-composites and hybrid materials that combine aluminum with ceramics or carbon fibers to achieve higher strength and wear resistance. For example, aluminum matrix composites (AMCs) are being tested for use in high-load transmission parts, offering superior performance while maintaining light weight. These materials could revolutionize industries like aerospace and motorsports, where every gram counts.

Additive manufacturing is another area of rapid advancement. 3D printing of aluminum parts allows for complex geometries that are impossible with traditional methods, enabling lightweight, optimized designs for transmissions. Techniques like binder jetting or directed energy deposition are becoming more accessible, reducing costs and lead times. In the future, we might see fully 3D-printed transmission systems that are custom-tailored for specific applications, improving efficiency and reducing waste. This technology also facilitates rapid prototyping, accelerating innovation cycles.

Smart materials and IoT (Internet of Things) integration are emerging trends. Aluminum transmission parts could be embedded with sensors to monitor conditions like temperature, vibration, and wear in real-time. This data can be used for predictive maintenance, preventing failures and extending lifespan. For instance, in industrial machinery, smart gears could alert operators to potential issues before they become critical, reducing downtime and costs. The combination of aluminum's properties with digital technologies opens up new possibilities for intelligent, connected systems.

Sustainability will continue to drive innovation, with a focus on improving recycling processes and reducing the carbon footprint of aluminum production. New methods for extracting aluminum from recycled sources more efficiently are under development, aiming for a closed-loop system where waste is minimized. Additionally, bio-based or green aluminum, produced using renewable energy, is gaining traction. These efforts align with global sustainability goals and consumer preferences for environmentally responsible products.

In conclusion, the future of aluminum transmission parts is filled with exciting possibilities. From advanced materials and additive manufacturing to smart technologies and enhanced sustainability, innovations will ensure that aluminum remains a cornerstone of modern engineering. By staying at the forefront of these trends, industries can leverage aluminum to create more efficient, reliable, and eco-friendly transmission systems for years to come.

В заключение, прочные алюминиевые детали передач представляют собой выдающееся решение для современных инженерных challenges, offering надежность, долговечность, и многочисленные преимущества across various отраслей. Их lightweight природа, коррозионная стойкость, и excellent thermal properties make them ideal for applications ranging from automotive to aerospace. Through advanced manufacturing processes и rigorous testing, these parts ensure high performance и safety. Экономические и экологические выгоды further underscore their value, supporting sustainability и cost-effectiveness. As innovations continue to emerge, the role of aluminum in transmission systems will only grow, driving progress toward more efficient и sustainable future. Мы encourage engineers и decision-makers to consider aluminum for their next projects, leveraging its full potential to achieve superior results.