В современном мире высокотехнологичного производства точное литье металлов играет ключевую роль, обеспечивая создание сложных, надежных и экономически эффективных компонентов. Эта технология стала незаменимой в таких отраслях, как аэрокосмическая, автомобильная, медицинская и электронная промышленность, где требования к точности, прочности и миниатюризации постоянно растут. В этой статье мы подробно рассмотрим, почему точное литье металлов является основой для инноваций и как оно способствует развитию высокотехнологичных производственных процессов.

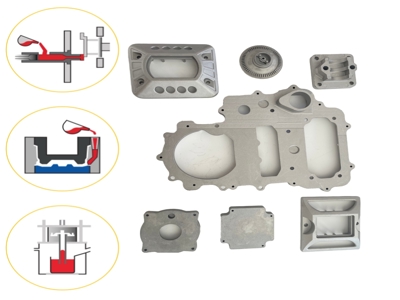

Точное литье металлов — это процесс изготовления металлических деталей с высокой точностью размеров и отличным качеством поверхности. Оно включает в себя такие методы, как литье под давлением, литье по выплавляемым моделям и литье в кокиль, которые позволяют производить компоненты с минимальными допусками и высокой повторяемостью. Этот процесс начинается с создания точной модели или формы, которая заполняется расплавленным металлом. После охлаждения и затвердевания получается готовая деталь, требующая минимальной последующей обработки. Точное литье особенно ценится за свою способность производить сложные геометрии, которые трудно или невозможно достичь другими методами обработки, такими как механическая обработка или штамповка.

Исторически литье металлов известно с древних времен, но современные технологии, такие как компьютерное моделирование (CAD/CAM) и автоматизация, революционизировали этот процесс. Сегодня точное литье использует передовые материалы, включая алюминиевые сплавы, титан, нержавеющую сталь и специальные сплавы, что делает его adaptable к различным промышленным needs. Например, в аэрокосмической отрасли точное литье позволяет создавать легкие и прочные компоненты для двигателей и структур, снижая вес и улучшая топливную эффективность.

Преимущества точного литья включают высокую производительность, возможность массового производства, снижение отходов материала и cost-effectiveness. Кроме того, оно поддерживает sustainability за счет возможности recycling металлов и уменьшения энергопотребления по сравнению с традиционными методами. Это делает точное литье не только технологическим прорывом, но и экологически ответственным выбором для modern manufacturing.

Современное точное литье металлов relies на разнообразных технологиях, каждая из которых tailored под specific applications. Одним из наиболее popular methods является литье под давлением (die casting), которое идеально подходит для производства large volumes of small to medium-sized parts с excellent dimensional accuracy. В этом процессе расплавленный металл injects под high pressure into a steel mold, resulting in fast cycle times and high efficiency. Die casting commonly uses alloys like zinc, aluminum, and magnesium, which are lightweight and have good mechanical properties.

Другой key technology — литье по выплавляемым моделям (investment casting), также известное как lost-wax casting. Этот метод involves creating a wax pattern of the desired part, coating it with a ceramic shell, and then melting out the wax to leave a cavity that is filled with molten metal. Investment casting produces parts with very smooth surfaces and complex geometries, making it ideal for applications in aerospace, jewelry, and medical devices. It allows for the use of a wide range of metals, including superalloys that withstand high temperatures.

Additionally, литье в кокиль (permanent mold casting) uses reusable molds made of metal, which are filled with molten metal gravity or low pressure. This method offers good surface finish and dimensional stability, suitable for parts like engine blocks and housings. Other advanced techniques include centrifugal casting, continuous casting, and vacuum casting, each with unique benefits. For instance, vacuum casting reduces porosity and improves material properties, critical for high-performance applications.

Innovations in technology, such as additive manufacturing (3D printing) for creating molds and patterns, have further enhanced precision casting. Computer-aided design (CAD) and simulation software allow for optimizing the casting process before production, reducing defects and improving yield. Automation and robotics integrated into casting lines increase consistency and reduce human error, pushing the boundaries of what is possible in metal fabrication.

Точное литье металлов finds extensive application in high-tech industries due to its ability to meet stringent requirements for precision, durability, and performance. In the aerospace sector, it is used to manufacture turbine blades, structural components, and landing gear parts. These components must withstand extreme conditions, such as high temperatures and pressures, and precise casting ensures they have the necessary strength and fatigue resistance. For example, nickel-based superalloys cast through investment casting are essential for jet engines, contributing to improved efficiency and safety.

In the automotive industry, precise casting is crucial for producing engine parts, transmission components, and lightweight body structures. The shift towards electric vehicles (EVs) has increased demand for cast parts in batteries and motors, where thermal management and weight reduction are key. Die-c aluminum parts help reduce vehicle weight, enhancing fuel efficiency and reducing emissions. Moreover, casting enables the integration of multiple functions into single components, simplifying assembly and lowering costs.

The medical field benefits from precise casting in the production of surgical instruments, implants, and diagnostic equipment. Titanium and stainless steel castings are common for orthopedic implants like hip and knee replacements, offering biocompatibility and long-term reliability. The high precision ensures that these devices fit perfectly and function as intended, improving patient outcomes. In electronics, casting is used for heat sinks, connectors, and enclosures that require excellent thermal conductivity and electromagnetic shielding.

Other industries, such as energy (e.g., wind turbine components), defense (e.g., weapon systems), and consumer goods (e.g., smartphones and appliances), also rely on precise metal casting. The versatility of the process allows for customization and innovation, driving progress across multiple sectors. As technology advances, new applications emerge, such as in additive manufacturing hybrids where casting complements 3D printing for large-scale production.

Точное литье металлов offers numerous advantages that make it a cornerstone of high-tech manufacturing. One of the primary benefits is its ability to produce complex shapes with high accuracy, reducing the need for secondary machining and saving time and resources. This leads to cost savings, especially in mass production scenarios. The process also provides excellent material properties, such as good strength-to-weight ratios and resistance to wear and corrosion, which are essential for demanding applications.

Another advantage is the flexibility in material selection. Casting can handle a wide range of metals and alloys, from common ones like aluminum and steel to exotic materials like titanium and cobalt-chrome. This allows manufacturers to choose the best material for specific performance criteria, such as high temperature resistance or electrical conductivity. Additionally, casting supports sustainability through material efficiency; near-net-shape production minimizes waste, and recycled metals can often be used, aligning with circular economy principles.

However, precise casting also faces challenges. Defects such as porosity, shrinkage, and inclusions can occur if the process is not tightly controlled, leading to scrap and increased costs. Overcoming these requires advanced process monitoring, quality control systems, and skilled labor. The initial investment in tooling and equipment can be high, particularly for methods like die casting, which need expensive molds. Environmental concerns, such as energy consumption and emissions from melting metals, must be addressed through innovations like energy-efficient furnaces and cleaner production techniques.

Despite these challenges, ongoing research and development are mitigating issues. For instance, simulation software helps predict and prevent defects, while automation improves consistency. The industry is also adopting greener practices, such as using renewable energy sources and developing low-emission casting processes. By addressing these challenges, precise casting continues to evolve and maintain its relevance in high-tech manufacturing.

The future of precise metal casting is bright, driven by technological advancements and increasing demands from high-tech industries. One major trend is the integration of digital technologies, such as Internet of Things (IoT) and artificial intelligence (AI), into casting processes. IoT sensors can monitor parameters like temperature and pressure in real-time, enabling predictive maintenance and optimizing production. AI algorithms analyze data to improve process control, reduce defects, and enhance efficiency.

Additive manufacturing, or 3D printing, is revolutionizing casting by allowing for the rapid prototyping of molds and patterns. This reduces lead times and costs for new product development. Hybrid approaches, where 3D printing is used to create complex cores or inserts for traditional casting, are gaining popularity, combining the benefits of both technologies. For example, in investment casting, 3D-printed patterns can be produced directly from digital designs, speeding up the process and allowing for greater design freedom.

Material science innovations are also shaping the future. New alloys with improved properties, such as higher strength or better corrosion resistance, are being developed specifically for casting applications. Nanotechnology is being explored to enhance material performance at the micro-level, potentially leading to cast parts with superior characteristics. Additionally, there is a growing focus on sustainability, with research into recycling methods, energy-efficient processes, and the use of biodegradable materials for patterns in investment casting.

Another emerging trend is the customization and personalization of cast parts. With advancements in digital design and manufacturing, it becomes feasible to produce small batches or even one-off components cost-effectively. This is particularly valuable in industries like healthcare, where patient-specific implants can be cast to exact specifications. As global industries continue to prioritize innovation and efficiency, precise metal casting will remain at the forefront, adapting to new challenges and opportunities.

В заключение, точное литье металлов действительно является ключом к высокотехнологичному производству, обеспечивая необходимую точность, эффективность и инновации для современных отраслей. От аэрокосмической и автомобильной промышленности до медицинских и электронных applications, этот process enables the creation of components that are essential for advancement and growth. С continued investments in technology, materials, and sustainability, точное литье будет и дальше evolve, supporting the development of smarter, greener, and more efficient manufacturing systems.

Для компаний, looking to stay competitive, adopting advanced casting techniques is not just an option but a necessity. By leveraging the benefits of precise casting, businesses can reduce costs, improve product quality, and contribute to a more sustainable future. As we move forward, collaboration between industry, academia, and government will be crucial in driving innovation and ensuring that precise metal casting remains a pillar of high-tech production.

Если вы interested in learning more about how precise metal casting can benefit your operations, contact experts in the field or explore training and resources available. The journey towards high-tech manufacturing starts with embracing proven technologies like metal casting, and the future holds endless possibilities for those who invest in it.