В современной промышленности алюминиевые детали играют ключевую роль благодаря своим уникальным свойствам: легкости, прочности, коррозионной стойкости и отличной обрабатываемости. Они широко используются в ремонте и сборке различного оборудования, от станков и автомобилей до аэрокосмической техники. Однако найти надежного поставщика, способного предоставить качественные детали в срок и по конкурентным ценам, может быть сложной задачей. В этой статье мы подробно рассмотрим, где и как заказать алюминиевые детали, чтобы обеспечить бесперебойную работу вашего предприятия.

Алюминий — один из самых распространенных металлов в мире, и его применение в промышленности продолжает расти. Легкость алюминиевых сплавов позволяет снизить общий вес оборудования, что особенно важно в таких отраслях, как авиация и автомобилестроение, где каждый килограмм влияет на эффективность и расход топлива. Кроме того, алюминий обладает высокой теплопроводностью и электропроводностью, что делает его идеальным для использования в электронике и системах охлаждения.

При ремонте и сборке оборудования надежность деталей критически важна. Некачественные компоненты могут привести к простоям, повышенным расходам на обслуживание и даже к авариям. Поэтому выбор поставщика, который гарантирует высокое качество продукции, является ключевым фактором успеха. В этой статье мы рассмотрим различные аспекты заказа алюминиевых деталей, включая методы производства, критерии выбора поставщиков и практические рекомендации.

Прежде чем заказывать детали, важно понимать, как они производятся. Это поможет вам выбрать наиболее подходящий метод для ваших нужд и оценить компетенцию потенциальных поставщиков.

ЧПУ (числовое программное управление) — это наиболее распространенный метод производства точных алюминиевых деталей. Он позволяет создавать complex geometries with high accuracy. Процесс involves using computer-controlled machines to remove material from a solid block of aluminum. Advantages include high precision, repeatability, and the ability to produce small batches or prototypes quickly. However, it can be more expensive for large volumes due to material waste.

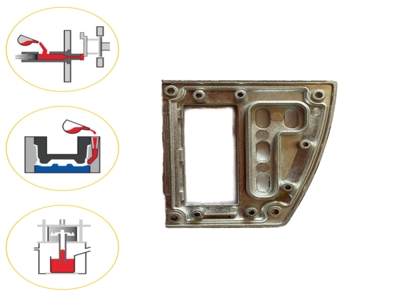

Литье — это процесс, при котором расплавленный алюминий заливается в форму и охлаждается для получения desired shape. It is ideal for mass production of complex parts with good surface finish. Common methods include sand casting, die casting, and investment casting. While casting is cost-effective for high volumes, it may require additional machining to achieve tight tolerances.

3D-печать increasingly used for prototyping and small-batch production of aluminum parts. It builds parts layer by layer from metal powder, allowing for highly complex designs that are difficult to achieve with traditional methods. Although it offers design freedom and reduces waste, it can be slower and more expensive for large-scale production.

These processes involve shaping aluminum using dies and pressure. Stamping is used for sheet metal parts, while forging improves strength and durability by aligning the metal's grain structure. They are suitable for high-strength applications but may not be as precise as CNC machining.

Choosing the right production method depends on factors such as volume, complexity, tolerance requirements, and budget. Discuss these aspects with potential suppliers to ensure they can meet your needs.

Selecting a reliable supplier is crucial for obtaining high-quality parts. Here are key factors to consider:

Look for suppliers with ISO 9001 certification or similar quality management systems. This ensures that they follow standardized processes for consistency. Additionally, check if they use high-quality aluminum alloys (e.g., 6061, 7075) and perform inspections like dimensional checks, hardness tests, and surface finish evaluations.

Choose suppliers with a proven track record in your industry. Read reviews, ask for case studies, and request references from previous clients. Experienced suppliers are more likely to understand your requirements and avoid common pitfalls.

Ensure the supplier has the necessary equipment and expertise for your chosen production method. For example, if you need CNC machined parts, they should have advanced CNC machines and skilled operators. Discuss their capacity to handle your order volume and lead times.

Compare quotes from multiple suppliers, but don't choose based solely on price. Low prices may indicate compromised quality. Negotiate payment terms that work for you, such as partial payments or discounts for bulk orders.

Consider the supplier's location and shipping options. Local suppliers may offer faster delivery and lower shipping costs, while international ones might provide cost savings but longer lead times. Ensure they have reliable packaging to prevent damage during transit.

A responsive supplier who communicates clearly can help resolve issues quickly. Evaluate their customer service during the inquiry process—prompt replies and willingness to answer questions are good signs.

By thoroughly vetting suppliers based on these criteria, you can minimize risks and ensure a smooth ordering experience.

There are numerous avenues to find suppliers for aluminum parts. Here’s a breakdown of effective strategies:

Websites like Alibaba, Thomasnet, and MFG.com connect buyers with manufacturers worldwide. These platforms allow you to browse profiles, compare quotes, and read reviews. Use filters to narrow down suppliers by location, certification, and capabilities.

Attending events such as IMTS (International Manufacturing Technology Show) or local trade fairs provides opportunities to meet suppliers in person, see their products, and discuss your needs directly. This can build trust and facilitate better negotiations.

Ask colleagues, industry associations, or online forums for recommendations. Personal referrals often lead to reliable suppliers who have already been vetted by others.

Use search engines to find suppliers specializing in aluminum parts. Check their websites for detailed information about services, and look them up on LinkedIn or other social media to gauge their activity and reputation.

Don’t overlook local machine shops or distributors. They may offer faster turnaround times and better support for urgent orders. Visit their facilities if possible to assess their operations.

Combining these approaches will help you create a shortlist of potential suppliers to evaluate further.

Once you’ve identified potential suppliers, follow these steps to place an order:

Provide detailed drawings or CAD files specifying dimensions, tolerances, material grade, surface finish, and any special requirements. Clear documentation reduces the risk of errors and ensures the supplier understands your expectations.

Send RFQs to multiple suppliers, including all necessary details. Ask for a breakdown of costs, lead times, and any minimum order quantities. Compare responses to identify the best fit.

Request samples before placing a large order. Test them for fit, function, and quality. This step is especially important for new suppliers to verify their capabilities.

Negotiate terms and sign a contract that outlines specifications, delivery dates, payment terms, and warranties. Ensure it includes clauses for quality assurance and dispute resolution.

Stay in touch with the supplier during production to address any issues early. Track the shipment to ensure timely delivery. Upon receipt, inspect the parts thoroughly before accepting them.

Provide feedback to the supplier and address any problems promptly. Building a long-term relationship can lead to better terms and reliability in future orders.

Following these steps will help you manage the ordering process efficiently and avoid common pitfalls.

The market for aluminum parts is evolving with advancements in technology and changing industry demands. Key trends include:

There is a growing emphasis on recycling aluminum, as it requires significantly less energy than primary production. Suppliers are adopting greener practices, which can be a factor in your selection if sustainability is a priority for your business.

Integration of IoT and AI in manufacturing allows for real-time monitoring and predictive maintenance, improving efficiency and quality. Look for suppliers who embrace these technologies to stay competitive.

Demand for customized parts is increasing, driven by industries like aerospace and medical devices. Suppliers are offering more flexible production options, such as on-demand manufacturing and rapid prototyping.

While globalization offers access to a wider range of suppliers, it also introduces risks like tariffs and logistical challenges. Diversifying your supplier base can mitigate these risks.

Staying informed about these trends will help you make strategic decisions when ordering aluminum parts.

Заказ надежных алюминиевых деталей для ремонта и сборки оборудования requires careful planning and due diligence. Start by understanding your requirements and the available production methods. Then, thoroughly evaluate suppliers based on quality, experience, and other criteria. Utilize both online and offline resources to find potential partners, and follow a structured ordering process to ensure success.

Remember, the cheapest option is not always the best—invest in quality to avoid costly downtime and repairs. Build strong relationships with suppliers for long-term benefits. As the industry continues to innovate, staying adaptable will help you navigate future challenges.

By applying the insights from this article, you can confidently source aluminum parts that meet your needs and contribute to the efficiency and reliability of your equipment.