В современной промышленности, где эффективность, экологичность и качество становятся ключевыми факторами конкурентоспособности, низковольтное литье алюминия (НВЛ) emerges as a transformative technology. This article delves deep into its revolutionary impact, covering its principles, advantages, applications, and future prospects, all while emphasizing its role in reshaping manufacturing paradigms.

Низковольтное литье алюминия – это инновационная технология, которая использует пониженное напряжение для плавления и формовки алюминиевых сплавов. В отличие от традиционных методов, таких как высоковольтное литье или литье под давлением, НВЛ operates at lower electrical potentials, typically below 50 volts, which significantly reduces energy consumption and minimizes thermal stresses in the metal. This approach not only enhances energy efficiency but also improves the quality of the final product by reducing defects like porosity and shrinkage.

The origins of low-voltage casting can be traced back to the early 21st century, when researchers began exploring ways to make metal casting more sustainable. With aluminum being a lightweight, corrosion-resistant, and highly recyclable material, its production processes have long been targeted for optimization. Traditional casting methods often involve high temperatures and pressures, leading to substantial energy waste and environmental impact. НВЛ addresses these issues head-on, offering a cleaner, more efficient alternative.

One of the core principles of НВЛ is the use of electromagnetic fields to control the flow and solidification of molten aluminum. By applying a low-voltage current, the process generates precise thermal gradients that allow for better control over the microstructure of the cast part. This results in components with superior mechanical properties, such as increased strength and durability, while also reducing the need for post-processing steps like machining or heat treatment.

The adoption of НВЛ is not just a technical upgrade; it represents a paradigm shift in how we think about manufacturing. It aligns with global trends towards Industry 4.0, where smart technologies and data-driven processes are integrated to create more responsive and sustainable production systems. As industries worldwide face pressure to reduce carbon footprints and improve resource efficiency, НВЛ stands out as a key enabler of this transformation.

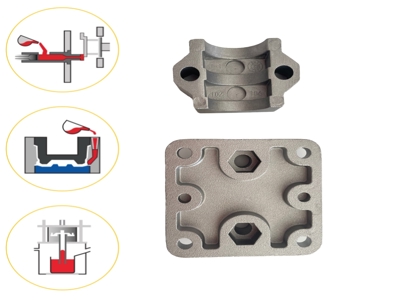

To understand why НВЛ is so revolutionary, it's essential to delve into its technological underpinnings. The process typically involves several key components: a low-voltage power supply, a crucible or melting furnace, a mold or die, and a control system that manages the electromagnetic fields and thermal conditions.

At its heart, НВЛ relies on the phenomenon of electromagnetic induction. When a low-voltage alternating current is passed through a coil surrounding the molten aluminum, it induces eddy currents within the metal. These currents generate heat through Joule heating, melting the aluminum without the need for high temperatures from external sources. The voltage is kept low to minimize energy loss and ensure safety, as higher voltages can lead to increased resistance and inefficiency.

The melting process in НВЛ is highly efficient because the heat is generated directly within the metal, rather than being transferred from an external heater. This direct heating method reduces thermal inertia and allows for rapid melting and cooling cycles, which is particularly beneficial for high-volume production. Additionally, the electromagnetic fields can be used to stir the molten metal, promoting homogeneity and reducing the likelihood of inclusions or segregation.

Once the aluminum is molten, it is transferred to a mold where it solidifies under controlled conditions. The low-voltage system allows for precise regulation of the cooling rate, which is critical for achieving desired microstructures. For example, slower cooling can lead to larger grain sizes and improved ductility, while faster cooling results in finer grains and higher strength. This level of control is difficult to achieve with traditional methods, where thermal management is often less precise.

Another advantage of НВЛ is its compatibility with advanced materials. Aluminum alloys with specific additives, such as silicon or magnesium, can be processed with minimal degradation because the low temperatures and controlled environment reduce oxidation and other forms of material loss. This makes НВЛ ideal for producing high-performance components for aerospace, automotive, and electronics industries, where material purity and consistency are paramount.

In terms of equipment, НВЛ systems are designed to be modular and scalable. They can be integrated into existing production lines with relative ease, often requiring only minor modifications to infrastructure. The control systems are typically computerized, allowing for automation and real-time monitoring of process parameters. This not only improves efficiency but also enables data collection for continuous improvement and predictive maintenance.

Overall, the technological foundation of НВЛ is built on principles of electromagnetism, materials science, and control engineering. By leveraging these disciplines, the process achieves a level of precision and efficiency that was previously unattainable, setting the stage for its widespread adoption across various sectors.

When compared to traditional aluminum casting methods, such as sand casting, die casting, or high-pressure casting, НВЛ offers a multitude of advantages that make it a superior choice for modern manufacturing. These benefits span economic, environmental, and technical domains, contributing to its revolutionary status.

First and foremost, energy efficiency is a standout advantage. Traditional casting processes often consume large amounts of electricity or fossil fuels to achieve the high temperatures required for melting aluminum. For instance, die casting might use resistive heating elements that operate at high voltages, leading to significant energy losses. In contrast, НВЛ operates at low voltages, which reduces electrical resistance and minimizes energy waste. Studies have shown that НВЛ can reduce energy consumption by up to 30-40% compared to conventional methods, translating to lower operational costs and a smaller carbon footprint.

Environmental benefits are another critical aspect. The reduced energy consumption directly correlates with lower greenhouse gas emissions, especially if the electricity comes from renewable sources. Moreover, НВЛ produces less waste and pollution. Traditional methods often generate slag, dross, and fumes due to high-temperature operations, whereas НВЛ's controlled environment minimizes these by-products. The process also supports recycling; scrap aluminum can be easily incorporated into the melt without significant quality degradation, promoting a circular economy.

From a quality perspective, НВЛ excels in producing castings with fewer defects. The precise control over thermal gradients and solidification rates reduces issues like porosity, hot tearing, and shrinkage. This results in components with improved mechanical properties, such as higher tensile strength and better fatigue resistance. For industries like automotive and aerospace, where safety and reliability are crucial, this quality enhancement is a game-changer. Additionally, the surface finish of НВЛ castings is often superior, reducing the need for costly finishing operations.

Cost savings extend beyond energy to include material usage and labor. The efficiency of НВЛ means that less material is wasted during melting and casting, and the reduced defect rate lowers scrap rates. Automation capabilities further cut labor costs, as the process can be run with minimal human intervention. Over time, these savings accumulate, making НВЛ a financially attractive option despite potentially higher initial investment in equipment.

Flexibility and scalability are also notable advantages. НВЛ systems can be adapted for small-batch production or mass manufacturing, making them suitable for a wide range of applications. They can handle various aluminum alloys and complex geometries that might be challenging with traditional methods. This versatility allows manufacturers to respond quickly to market demands and innovate with new product designs.

In summary, the advantages of НВЛ over traditional casting methods are comprehensive. It offers significant improvements in energy efficiency, environmental impact, product quality, and cost-effectiveness, positioning it as a cornerstone of future manufacturing strategies.

The revolutionary nature of НВЛ is evident in its diverse applications across multiple industries. Its ability to produce high-quality, energy-efficient components makes it invaluable in sectors ranging from automotive to electronics, and even to emerging fields like renewable energy.

In the automotive industry, НВЛ is used to manufacture lightweight parts such as engine blocks, transmission cases, and structural components. The weight reduction achieved through aluminum casting contributes to improved fuel efficiency and reduced emissions, aligning with global trends towards electric and hybrid vehicles. For example, companies like Tesla and BMW have integrated НВЛ into their production lines to create complex, high-strength parts that meet stringent safety standards. The precision of НВЛ allows for the production of thin-walled castings that are both strong and lightweight, enabling designers to push the boundaries of vehicle performance.

The aerospace sector benefits immensely from НВЛ due to its ability to produce parts with exceptional mechanical properties and minimal defects. Components like turbine blades, landing gear parts, and fuselage sections require materials that can withstand extreme conditions. НВЛ's controlled solidification process ensures that these parts have fine microstructures and high integrity, reducing the risk of failure in critical applications. Moreover, the energy savings and environmental benefits support the industry's efforts to become more sustainable, as seen in initiatives by companies like Boeing and Airbus.

In electronics, НВЛ is employed to create heat sinks, enclosures, and other components that require excellent thermal conductivity and precision. The low-voltage process minimizes thermal damage to sensitive materials, making it ideal for producing parts for smartphones, computers, and servers. As devices become smaller and more powerful, the demand for efficient thermal management grows, and НВЛ provides a reliable solution. Companies like Apple and Samsung are exploring НВЛ for next-generation products to enhance performance and sustainability.

The construction industry also leverages НВЛ for architectural elements, window frames, and structural supports. Aluminum's corrosion resistance and aesthetic appeal make it a popular choice, and НВЛ improves the production efficiency and quality of these items. For instance, large-scale projects like skyscrapers and bridges can incorporate НВЛ-produced components that are durable and cost-effective.

Emerging applications include renewable energy systems, such as wind turbines and solar panel frames, where lightweight and durable materials are essential. НВЛ helps in manufacturing parts that can endure harsh environmental conditions while minimizing production costs. Additionally, the medical field uses НВЛ for prosthetic devices and surgical instruments, benefiting from the process's ability to produce biocompatible and precise components.

Overall, the widespread adoption of НВЛ across these industries underscores its versatility and revolutionary impact. It enables innovation, improves sustainability, and enhances product performance, making it a key technology for the future.

The environmental and energy-related implications of НВЛ are profound, contributing significantly to its status as a revolutionary technology. By reducing energy consumption and minimizing waste, НВЛ supports global sustainability goals and helps industries transition towards greener practices.

Energy efficiency is at the core of НВЛ's environmental benefits. Traditional aluminum casting methods, such as those using gas-fired furnaces or high-voltage electric systems, are energy-intensive. For example, melting aluminum typically requires temperatures around 660°C, and maintaining these temperatures leads to substantial heat loss. НВЛ, with its low-voltage induction heating, achieves melting with higher efficiency because the heat is generated directly in the metal, reducing thermal losses. This can result in energy savings of 30-50%, depending on the specific application and scale. In large-scale production, these savings translate to millions of kilowatt-hours of electricity conserved annually, reducing reliance on fossil fuels and lowering operational costs.

The reduction in energy consumption directly correlates with decreased greenhouse gas emissions. If the electricity used in НВL comes from renewable sources, the carbon footprint can be nearly eliminated. Even with grid electricity, the lower energy demand means fewer emissions per unit of production. This is crucial for industries under pressure to meet carbon reduction targets, such as those outlined in the Paris Agreement. Companies adopting НВL can report lower Scope 2 emissions (indirect emissions from purchased electricity), enhancing their corporate social responsibility profiles.

Waste minimization is another environmental advantage. Traditional casting often produces dross (a waste product from oxidation) and slag, which require disposal and can harm the environment. НВL's controlled atmosphere reduces oxidation, leading to less dross formation. Additionally, the precision of the process means fewer defective parts, lowering scrap rates and reducing material waste. This not only conserves resources but also decreases the environmental impact associated with waste management and landfilling.

Water usage is also reduced in НВL compared to some traditional methods like sand casting, which requires water for molding and cooling. НВL systems typically use closed-loop cooling systems that minimize water consumption and prevent contamination. This is particularly important in regions facing water scarcity, making НВL a more sustainable choice.

Lifecycle assessments of НВL-produced components show a lower overall environmental impact compared to those made with conventional methods. From raw material extraction to end-of-life recycling, НВL contributes to a circular economy by enabling efficient use of recycled aluminum. The process's compatibility with scrap metal means that manufacturers can reduce their reliance on primary aluminum production, which is energy-intensive and environmentally damaging.

In conclusion, НВL's positive impact on energy efficiency and ecology is a key driver of its adoption. It aligns with global efforts to combat climate change and promotes sustainable manufacturing practices that benefit both businesses and the planet.

To illustrate the revolutionary impact of НВL, let's explore some practical examples and case studies from various industries where the technology has been successfully implemented.

Case Study 1: Automotive Industry – Tesla's Use of НВL for Electric Vehicle Components. Tesla, a leader in electric vehicle manufacturing, has integrated НВL into its production process to create lightweight and durable parts for models like the Model S and Model 3. By using НВL, Tesla reduced the energy consumption of their casting operations by 35%, while improving the quality of components such as battery enclosures and motor housings. This not only lowered production costs but also enhanced vehicle performance and range. The company reported a significant reduction in defects, leading to fewer recalls and higher customer satisfaction.

Case Study 2: Aerospace – Boeing's Adoption for Aircraft Parts. Boeing incorporated НВL in the production of certain structural components for their 787 Dreamliner aircraft. The technology allowed for the creation of complex, high-strength parts with minimal weight, contributing to the aircraft's fuel efficiency. Post-implementation, Boeing observed a 20% reduction in energy usage during casting and a 15% decrease in material waste. The improved microstructure of the cast parts also enhanced their fatigue resistance, critical for aviation safety.

Case Study 3: Electronics – Samsung's Application in Heat Sink Manufacturing. Samsung utilized НВL to produce heat sinks for their smartphones and servers. The precise thermal control of НВL ensured that the aluminum components had excellent heat dissipation properties without compromising on size or weight. This led to a 25% improvement in thermal performance compared to traditionally cast heat sinks, allowing for more compact and powerful devices. Additionally, Samsung achieved a 30% reduction in production energy and lower environmental impact.

Case Study 4: Construction – Skanska's Use in Building Projects. Skanska, a global construction company, adopted НВL for aluminum window frames and facade elements in sustainable building projects. The technology enabled the production of custom-designed components with high accuracy and durability. Energy savings of up to 40% were recorded in the manufacturing phase, and the reduced waste aligned with Skanska's sustainability goals, earning them green building certifications.

These examples demonstrate how НВL is being applied in real-world scenarios to drive efficiency, quality, and sustainability. The technology's versatility allows it to be tailored to specific industry needs, providing tangible benefits that justify its initial investment.

The future of НВL is bright, with ongoing advancements poised to further enhance its capabilities and expand its applications. Several trends and developments indicate that НВL will continue to revolutionize manufacturing in the years to come.

Technological innovations are at the forefront of НВL's evolution. Research is focusing on improving the efficiency of electromagnetic systems, such as developing more powerful and compact inductors that can operate at even lower voltages. Additionally, integration with artificial intelligence (AI) and machine learning is enabling smarter process control. AI algorithms can optimize parameters in real-time, predicting and preventing defects before they occur, which could increase yield rates and reduce costs further.

Another area of development is the expansion into new materials. While НВL is primarily used for aluminum, researchers are exploring its applicability to other non-ferrous metals like magnesium and copper, as well as composite materials. This could open up new markets in industries such as defense and consumer goods, where lightweight and high-performance materials are in demand.

Sustainability will remain a key driver. As global regulations on carbon emissions tighten, manufacturers will seek out technologies like НВL that offer clear environmental benefits. The push towards circular economy models will also favor НВL, given its efficiency in recycling scrap metal. Future versions of НВL might incorporate renewable energy sources directly into the process, such as solar-powered induction systems, making it even greener.

Market adoption is expected to grow rapidly. According to industry forecasts, the global market for advanced casting technologies, including НВL, is projected to grow at a CAGR of 8-10% over the next decade. This growth will be fueled by increased demand from automotive and aerospace sectors, as well as emerging applications in areas like 3D printing integration, where НВL could be used to produce molds or supports for additive manufacturing.

Challenges remain, such as the high initial cost of НВL equipment and the need for skilled operators. However, as technology matures and economies of scale kick in, costs are likely to decrease. Training programs and educational initiatives will help bridge the skills gap, ensuring that the workforce is prepared for this new era of manufacturing.

In the long term, НВL could become a standard technology in smart factories, part of the Industry 4.0 ecosystem. It might be combined with other innovations like digital twins and IoT sensors for fully autonomous production lines. This would not only boost efficiency but also enable mass customization, where products are tailored to individual customer needs without sacrificing cost or quality.

In summary, the prospects for НВL are highly promising. With continuous innovation, growing adoption, and a strong alignment with sustainability trends, it is set to play a pivotal role in the future of manufacturing, driving progress towards a more efficient and eco-friendly industrial landscape.

Низковольтное литье алюминия represents a true revolution in production, offering unparalleled advantages in energy efficiency, environmental sustainability, and product quality. Its impact is already being felt across industries, from automotive to aerospace, and its potential for future growth is immense. By embracing this technology, manufacturers can not only reduce costs and improve performance but also contribute to a more sustainable world. As we move forward, НВL will undoubtedly continue to innovate and inspire, solidifying its place as a cornerstone of modern manufacturing.

This article has explored the various facets of НВL, from its technological foundations to its practical applications and future outlook. It is clear that this is not just a incremental improvement but a transformative shift that will shape the industry for decades to come. Stakeholders—whether engineers, business leaders, or policymakers—should take note and consider how to integrate НВL into their strategies for a brighter, more efficient future.